The Main Scraper Heat Exchanger Manufacturer In The World

The Scraped Surface Heat Exchanger (SSHE) is an important equipment widely used in food, pharmaceutical, chemical and other industries, especially for the fluid with high viscosity, easy crystallization or containing solid particles. Due to its advantages of efficient heat transfer, reduced scaling and uniform temperature control, many well-known companies around the world provide scraper heat exchangers, the following is a few of the world's famous scraper heat exchanger manufacturers and their related technologies.

1. Alfa Laval

Headquarters: Sweden

Headquarters: Sweden

Official website: alfalaval.com

Alfa Laval is one of the world's leading suppliers of heat exchange equipment, and its products are widely used in food, pharmaceutical, chemical and other fields. Alfa Laval's scraper heat exchangers use advanced heat exchange technology, which can effectively improve the heat exchange efficiency, prevent material scaling, and ensure product quality.

Alfa Laval's "Contherm" and "Convap" series of scraper heat exchangers are suitable for handling high viscosity and easily crystallized materials such as margarine, cream, syrups, chocolate, etc. The performance of its equipment focuses on energy efficiency and the stability of continuous operation.

Product features:

• Efficient heat exchange performance, able to provide a large heat exchange area in a small volume.

• Automatic cleaning system to ensure long-term operation of equipment without scaling.

• Precise temperature control system for complex heat transfer requirements.

2. SPX Flow (USA)

Headquarters: United States

Official website: spxflow.com

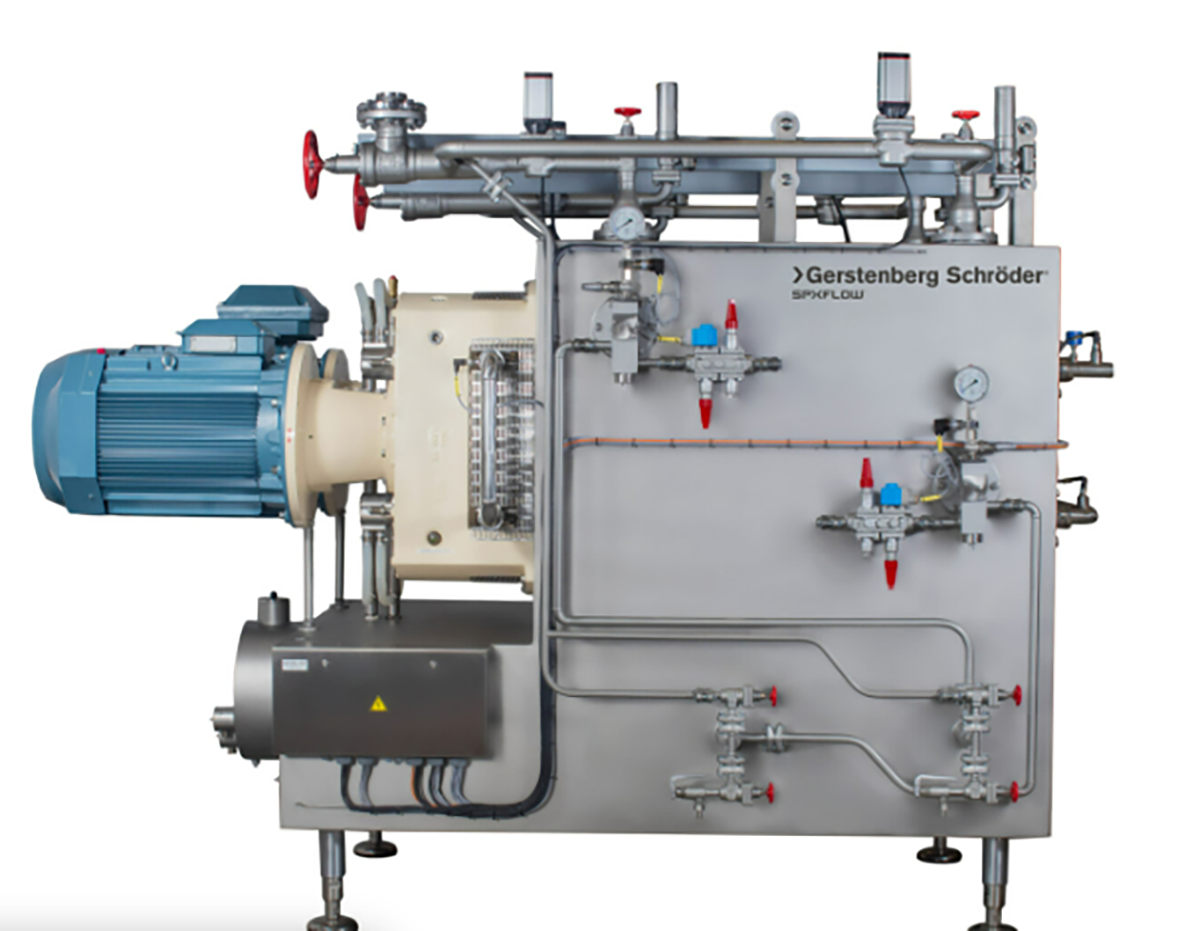

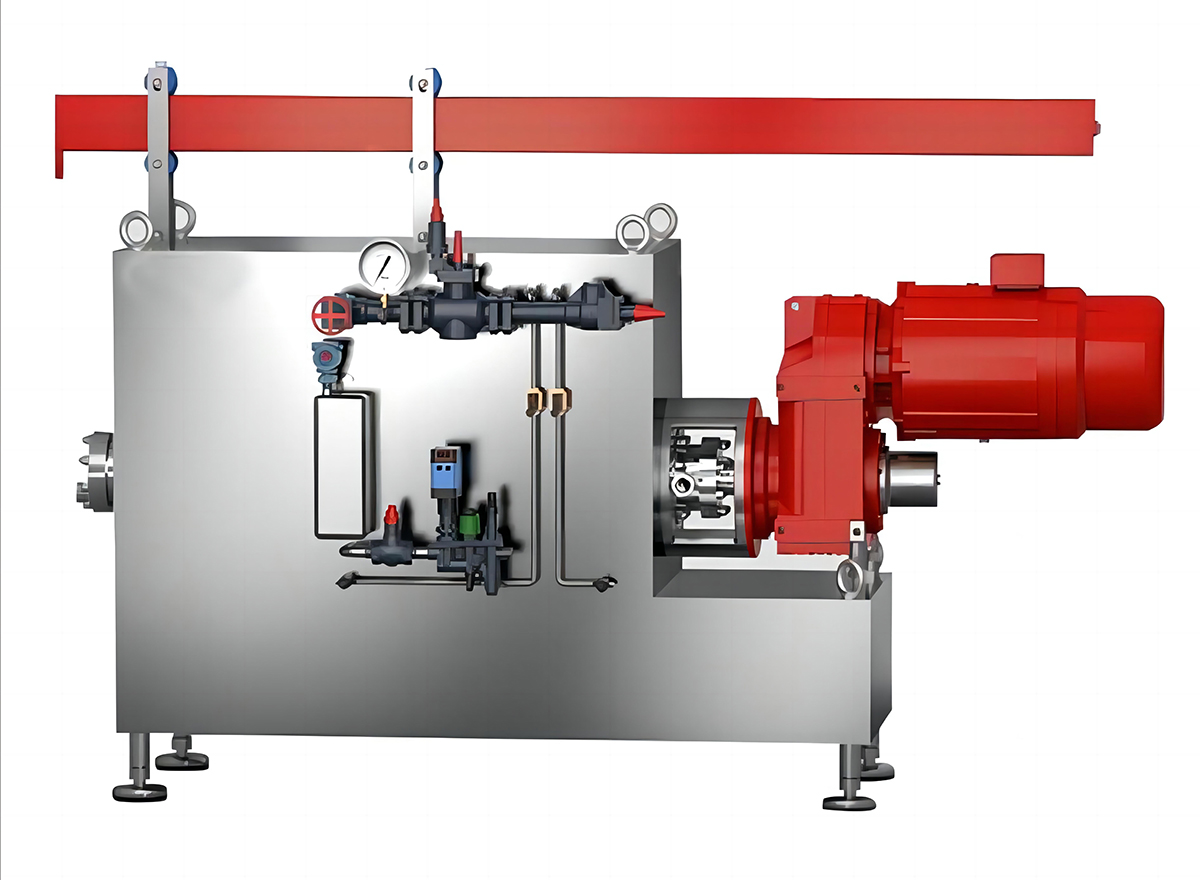

SPX Flow is an international fluid handling technology company that offers various types of heat transfer equipment, and scraper heat exchangers are one of its main products. Its Votator brand is the world's leading brand of scraper heat exchangers designed for the food and beverage, dairy and chemical industries.

SPX Flow's scraper heat exchangers use efficient heat exchange technology and have a unique scraper design to prevent material scaling on the heat exchange surface and improve heat conduction. The Votator range of products is available in a variety of specifications and configurations to suit the needs of different scales and production processes.

Product features:

• Excellent heat transfer performance for heating and cooling of high viscosity fluids.

• The scraper cleaning function keeps the heat exchange surface clean to ensure long-term operation of the equipment.

• Provide customized designs to meet different industrial needs.

3. HRS Heat Exchangers (UK)

Headquarters: United Kingdom

Official website: hrs-heatexchangers.com

HRS Heat Exchangers specialises in providing efficient heat exchange solutions, with particular expertise in the design of scraper heat exchangers for the food and chemical industries. Its R series scraper heat exchangers have a place in the global market, especially for dairy products, food processing, syrup production and other fields.

HRS's plate heat exchangers use special scraper technology to prevent crystallization, scaling and other problems during heat transfer, ensuring heat transfer efficiency and product quality in the production process.

Product features:

• High performance: Efficient heat transfer is maintained even when handling high viscosity and solid particle containing materials.

• Anti-scaling design: the scraper regularly cleans the heat exchange surface to reduce the scaling problem of materials.

• Energy saving: Optimized heat transfer design, high energy efficiency.

4. GEA Group (Germany)

Headquarters: Germany

Official website: gea.com

GEA Group is a leading global supplier of equipment to the food and chemical industries, and its scraper heat exchanger technology is known for its stability and reliability. GEA's HRS series of scraper heat exchangers are widely used in the dairy, beverage, chemical and other industries, and are particularly good at handling the heat transfer needs of high-viscosity, low-flow fluids.

GEA's scraper heat exchangers are designed to optimize heat exchange efficiency and are equipped with an efficient automatic cleaning system to reduce maintenance costs due to scaling in production.

Product features:

• Designed for high viscosity materials to provide stable heat transfer.

• Optimized structural design reduces energy consumption and improves production efficiency.

• Strong cleanliness, reduce cleaning and maintenance costs.

5. SINO-VOTATOR (China)

Headquarters: China

Official website: www.sino-votator.com

SINO-VOTATOR is a well-known manufacturer of scraper heat exchangers in China, whose equipment is widely used in the food, chemical and pharmaceutical industries. SINO-VOTATOR's scraper heat exchangers use international advanced technology, especially suitable for the production of margarine, butter, chocolate, syrup and other products.

SINO-VOTATOR offers a wide range of types of scraper heat exchangers, from small equipment to large production lines, and its products are known for their efficiency, energy saving and durability.

Product features:

• Designed for high viscosity fluids and adaptable to complex production processes.

• Can be customized according to customer needs, available in a variety of models and sizes.

• Excellent performance stability and reliability, reducing equipment failure and maintenance costs.

6. Tetra Pak (Sweden)

Headquarters: Sweden

Official website: tetrapak.com

Tetra Pak is a key supplier of equipment to the global food and beverage industry, and its scraper heat exchanger technology is used for heating and cooling dairy products, beverages, and other liquid foods. Tetra Pak's scraper heat exchangers use advanced heat exchange technology to efficiently and evenly process different types of materials.

Tetra Pak's equipment is widely used in the dairy industry, including the production of cream, margarine, ice cream, etc.

Product features:

• Efficient heat exchange capability, suitable for many different materials.

• Optimized design reduces energy consumption and increases production efficiency.

• Provide a full range of technical services from equipment selection to installation and commissioning.

Sum up

The scraper heat exchanger is an important equipment for processing fluid with high viscosity, easy crystallization or containing solid particles, which is widely used in food, pharmaceutical, chemical and other industries. Several of the world-renowned manufacturers of scraper heat exchangers listed above have advanced technology and rich experience to provide efficient and reliable heat transfer solutions according to customer needs. When selecting the right equipment supplier, in addition to considering the performance of the equipment, it is also necessary to consider the energy efficiency, stability and after-sales service of the equipment.

Post time: Feb-10-2025