What is Shortening?

First, a quick definition: Shortening is a solid fat made from vegetable oils, animal fats, or a combination. Its primary function is to "shorten" or break up the gluten strands in baked goods, creating a tender, flaky texture (e.g., in pie crusts, biscuits, and cookies).

The core technological challenge is turning liquid oils into a stable, semi-solid, plastic fat. This is achieved through two main processes: Hydrogenation and Interesterification, followed by Tempering.

The Core Processing Steps

The journey from raw oil to finished shortening involves several key stages:

1. Oil Selection and Blending

- Purpose: To create a base oil blend with the desired fatty acid profile for the final product's functionality (melting point, solid fat content, etc.).

- Process: Different refined, bleached, and deodorized (RBD) oils are measured and mixed. Common oils include soybean, palm, cottonseed, canola, and palm kernel oil.

2. Hydrogenation (Traditional Method)

- Purpose: To increase the melting point and stability of the liquid oil by making it more saturated.

- Process: The blended oil is heated in a pressurized reactor in the presence of a nickel catalyst and hydrogen gas.Note: This process creates trans fats, which are now heavily regulated and disliked due to health concerns. This has led to the rise of alternative technologies.

- Hydrogen atoms are added to the unsaturated double bonds in the fatty acid chains.

- This converts liquid oils (unsaturated) into semi-solid or solid fats (saturated and trans fats).

3. Interesterification (Modern Method)

- Purpose: To rearrange the fatty acids on the glycerol backbone of the triglyceride molecules without creating trans fats. This allows manufacturers to create a fat with the right melting and crystallization properties from a blend of oils.

- Process:Result: A trans-fat-free shortening base with excellent functional properties.

- Chemical IE: Uses a sodium methoxide catalyst to break and randomly reassemble the fatty acids.

- Enzymatic IE: Uses specific enzymes (e.g., lipases) as a catalyst. This is more precise and allows for targeted restructuring but is more expensive.

4. Blending and Emulsification

- The hardened base fat is blended with liquid oil to achieve the exact required Solid Fat Index (SFI) – a measure of hardness across different temperatures.

- Emulsifiers (e.g., monoglycerides, lecithin) are added to improve texture, volume, and shelf life in the final baked product.

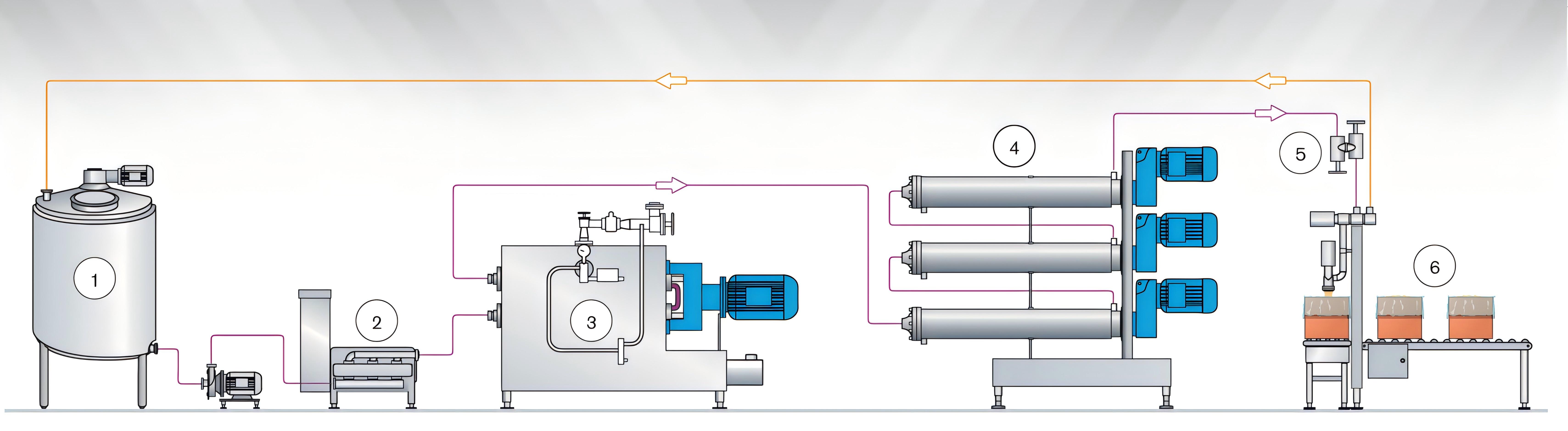

5. Cooling and Solidification (Chilling & Crystallization)

This is the most critical step for creating the final structure and "plasticity" (spreadability) of the shortening.

- Process: The melted fat mixture is pumped through a Votator or scraped-surface heat exchanger (SSHE).

- A Unit (Chiller): The fat is rapidly cooled under high pressure and agitation. This promotes the formation of many small beta-prime (β') crystals, which are ideal for smooth, fine-textured, and plastic shortening.

- B Unit (Temperer): The chilled fat is then worked in a pin-worker or quiescent tube. This kneads the crystallizing fat to ensure proper crystal formation and prevent large, grainy beta (β) crystals.

6. Tempering and Packaging

- The still-warm, crystallizing shortening is packaged (in tubs, cubes, or large containers).

- The packaged shortening is placed in temperature-controlled warehouses (tempering rooms) for 24-72 hours.

- Purpose of Tempering: This allows the crystal structure to stabilize completely into the desired β' form, ensuring a consistent, smooth texture and shelf stability.

7. Storage and Shipping

- The tempered shortening is stored and shipped under controlled temperatures to maintain its quality and plasticity.

Key Technological Concepts

- Plasticity: The property that allows shortening to be spread and mixed easily. It depends on having a mix of solid crystals and liquid oil within a specific temperature range (the "plastic range").

- Crystal Structure: The type of fat crystal is crucial.Solid Fat Index (SFI): A curve that measures the percentage of solid fat in a shortening across a range of temperatures. It is the primary tool for predicting a shortening's performance in a specific application (e.g., a pie crust shortening and an icing shortening have very different SFI curves).

- Beta-Prime (β') crystals: Small, needle-like crystals that form a fine network capable of holding large amounts of liquid oil. This creates a smooth, creamy, and highly plastic shortening. This is the desired form.

- Beta (β) crystals: Large, coarse, grainy crystals that result in a gritty, brittle, and non-plastic fat (e.g., the graininess in old butter).

Summary of Modern Shortening Production Flow

Evolution of the Technology

The trend is moving sharply away from hydrogenation (due to trans fat bans) and towards:

- Interesterification (chemical and enzymatic).

- Using naturally semi-solid oils like Palm Oil and its fractions (e.g., palm olein, palm stearin), often blended with other stable liquid oils like high-oleic sunflower or canola oil.

- Full Hydrogenation: Fully hydrogenating an oil (which creates fully saturated, trans-fat-free stearine) and then blending it with liquid oil. This is different from partial hydrogenation, which created trans fats.

The goal of modern shortening technology is to achieve the perfect functional properties for baking and frying without the use of artificial trans fats.

Post time: Sep-08-2025