The Origin of Scraped Surface Heat Exchangers

The origin and development of scraped surface heat exchangers can be traced back to the early 20th century. Their creation was not an overnight success but rather a response to the inherent limitations of traditional heat exchangers when dealing with specific materials.

Core Origin: 1920s - 1930s

The concept and initial design of scraped surface heat exchangers were mainly formed during this period, driven by the food industry, particularly in the production of margarine and ice cream.

1. Problems to be Solved:

o High Viscosity Materials: Materials like butter, ice cream mix, and jam are extremely viscous and have poor flowability in traditional tube or plate heat exchangers, easily clogging and resulting in very low heat transfer efficiency.

o Shear Sensitivity: The formation of fat crystals or ice crystals in these materials requires precise control. Intense or uneven cooling can lead to a coarse texture and poor taste.

o Fouling and Coking: Materials containing sugar or protein tend to solidify and caramelize on heating surfaces, not only affecting heat transfer but also causing product deterioration and difficulty in equipment cleaning.

2. Pioneers in Technology:

o One of the earliest patents for scraped surface heat exchangers can be traced back to the late 1920s to early 1930s. For instance, around 1928, engineers at Gerhard Company in Germany (later part of the APV Group) made pioneering work in this field.

o Another key figure was C. O. (Charlie) Linn, who designed the first commercially successful scraped surface heat exchanger for the Votator division of Girdler Corporation in the United States (around 1933-1935). This device was originally invented for the continuous production of margarine. The name "Votator" even became synonymous with scraped surface heat exchangers for a long time.

Innovative Points of Working Principle

The core design of scraped surface heat exchangers ingeniously addresses the above problems:

• Scraping Action: Inside the heat exchange cylinder, a rotor equipped with scrapers rotates at high speed. The scrapers, under the force of centrifugal force or springs, closely adhere to the cylinder wall, constantly scraping off the material film on the inner wall.

• Four Major Advantages:

1. Continuous Renewal of Heat Transfer Surface: Prevents material adhesion and fouling, maintaining extremely high heat transfer efficiency.

2. Uniform Mixing and Shearing: Ensures uniform heating and cooling of the entire material and provides controllable shear force, which is crucial for the crystallization process (such as fat crystallization and ice crystal formation).

3. Handling of Extremely High Viscosity: The mechanical scraping and pushing action enables it to handle pasty, creamy, and even granular fluids that traditional heat exchangers cannot handle.

4. Extremely Short Residence Time: The material passes through the heat exchanger in a thin film, making it highly suitable for heat-sensitive materials and maximizing the preservation of product flavor, color, and nutrition.

Development and Popularization

• 1940s - 1950s: With the acceleration of food industrialization before and after World War II, scraped surface heat exchangers were rapidly applied in the dairy, jam, and sauce industries. Continuous freezing of ice cream was another milestone application.

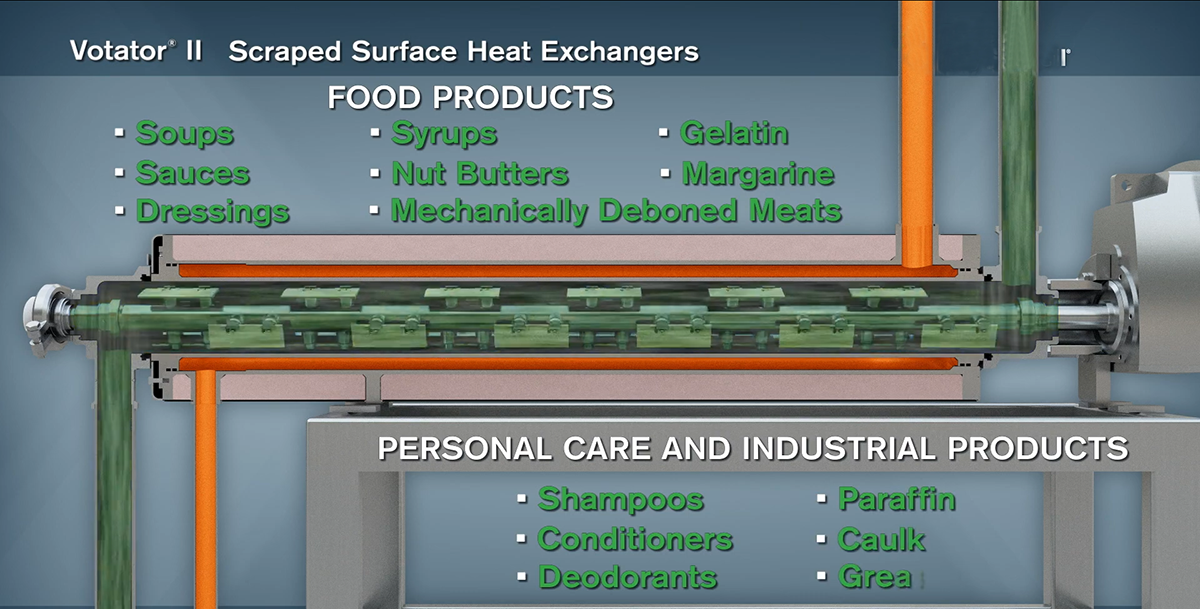

• 1960s to Present: Their application fields have expanded from the food industry to chemical, pharmaceutical, petrochemical, and plastic polymer industries. They are used to handle challenging fluids such as polymer melts, paraffin, asphalt, cosmetics, and pharmaceuticals.

• Technological Progress: Modern scraped surface heat exchangers have made significant advancements in materials (such as the use of wear-resistant and corrosion-resistant hard coatings), sealing technology, automation control (precise control of temperature, pressure, and speed), and modular design.

Summary

The origin of the scraper heat exchanger can be precisely located in the 1920s and 1930s. It was invented to meet the process demands of continuous heating, cooling, crystallization and sterilization of high-viscosity and heat-sensitive materials in the food industry. Its invention was a significant milestone in the history of process industry equipment, expanding the simple "heat exchange" function to a combined operation of "heat exchange and mechanical processing". To this day, it still plays an irreplaceable role in many industrial fields.

Post time: Oct-20-2025