What is an ammonia refrigeration system?

An ammonia refrigeration system is an industrial refrigeration system that uses ammonia (NH₃) as the refrigerant. It utilizes the principle that ammonia absorbs a large amount of heat during evaporation to provide cooling for industrial production processes that require low temperatures (such as food freezing, refrigeration, chemical production, ice sports venues, etc.).

Due to its high efficiency, economic nature and the fact that it does not damage the ozone layer (ODP = 0), ammonia is the preferred refrigerant in the fields of large-scale industrial and commercial refrigeration.

Core working principle (single-stage compression refrigeration cycle)

The operation of the ammonia cooling system follows the basic vapor compression refrigeration cycle, which mainly consists of four processes:

Compression: The ammonia vapor at low temperature and low pressure is drawn in by the compressor and compressed, turning into superheated vapor at high temperature and high pressure.

Condensation: Ammonia vapor at high temperature and high pressure enters the condenser, where it is cooled by cooling water or air, releasing heat and condensing into a high-pressure, normal-temperature ammonia liquid.

Throttling: The high-pressure ammonia liquid passes through the throttling valve (such as a expansion valve), and the pressure drops sharply. Some of the liquid vaporizes, turning into a mixture of low-temperature and low-pressure vapor and liquid.

Evaporation: Low-temperature ammonia enters the evaporator (such as a cooling fan or heat exchanger), absorbs the heat from the cooled space (cold storage), and completely evaporates into a low-temperature and low-pressure vapor. This vapor is then re吸入 by the compressor and completes the cycle.

Simple analogy: Just like how the human body sweats to cool down, when the sweat (ammonia solution) evaporates, it absorbs heat from the skin (the cooled part), making the skin feel cool.

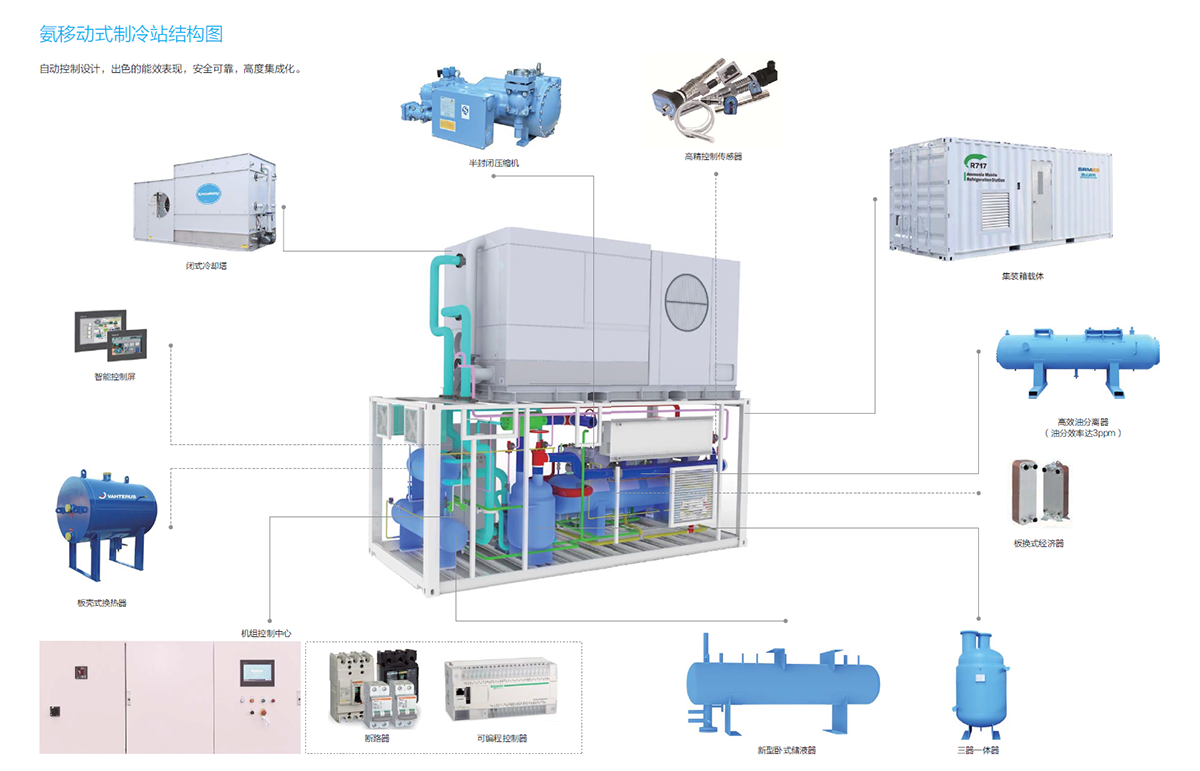

Main Components

Compressor: The "heart" of the system. Common types include piston, screw, and centrifugal. Screw compressors are the most widely used in modern medium and large-sized systems due to their high efficiency and flexible capacity adjustment.

Condenser: The "heat exchanger" of the system. It removes the heat from the compressed ammonia gas. It is divided into water-cooled type (high efficiency, requires cooling tower) and evaporative cooling type (water-saving, widely used).

Throttle device: such as expansion valve, float valve. It controls the flow rate and pressure of the ammonia liquid entering the evaporator.

Evaporator: The "cold output end" of the system. Installed in the cold storage or processing area, ammonia evaporates and absorbs heat within it. Common types include air coolers (with forced convection) and coil pipes (with natural convection).

Liquid storage tank: Stores the ammonia liquid after condensation, balancing the supply and demand of the system.

Oil separator and oil collector: Separate and recover the lubricating oil carried out by the compressor exhaust, ensuring the efficient operation of the system.

Gas-liquid separator: Protects the compressor by preventing the unevaporated ammonia liquid from entering and causing "liquid impact".

Control system: The "brain" of modern systems. It includes PLCs, sensors, actuators, etc., and is responsible for achieving automatic control, safety protection, and energy regulation.

Main types of systems

Direct expansion system: Ammonia is directly evaporated in the evaporator to achieve cooling. It has the highest efficiency, but it requires extremely strict pipe sealing, and its application has decreased.

Indirect cooling system:

Ammonia/saline water system: Ammonia first cools the saline water (such as calcium chloride solution), and then the low-temperature saline water is sent to each cooling point by a pump. The safety distance is far, but the energy efficiency is relatively low.

Ammonia/Carbon Dioxide Cascade System: The Current Mainstream and Trend. Ammonia operates at the high-temperature stage in the cycle, condensing carbon dioxide; carbon dioxide operates at the low-temperature stage evaporating for cooling. Combining the high efficiency of ammonia and the safety of carbon dioxide (non-toxic at low temperatures and moderate pressure), it is the preferred solution for large-scale refrigeration and freezing plants.

Gravity liquid supply system: It supplies liquid to the evaporator by utilizing the static pressure of the liquid column. It is stable and reliable, but requires a large amount of ammonia injection, and is commonly seen in older systems.

Liquid pump supply system: The pump is used to forcibly convey the low-pressure ammonia liquid to the evaporator. It has high heat exchange efficiency and uniform liquid supply, and is widely applied.

Highlighting the advantages

High efficiency and energy saving: The latent heat value of ammonia is high, and it consumes less electricity per unit of cooling capacity, resulting in low operating costs.

Environmental protection: ODP = 0, GWP = 0 (Global Warming Potential), it is a naturally environmentally friendly refrigerant.

Economy: Low price, easy to obtain.

Excellent heat transfer performance: High heat exchange efficiency with the metal pipe wall.

Easy leak detection: It has a strong pungent odor, and even a small amount of leakage can be detected.

Challenges and safety considerations (of utmost importance!)

Ammonia is toxic (Class 2) and flammable (Class B2L), so safety is the primary principle in design, installation, and operation.

Toxicity: Leakage can cause severe damage to people's eyes and respiratory system. High concentrations can be fatal.

Flammability: When the concentration in the air reaches 15% to 28%, it can explode upon contact with a flame.

Safety measures:

Computer room isolation: Main equipment such as compressors and liquid storage tanks should be placed in a separate, well-ventilated computer room.

Leak detection and alarm: Ammonia concentration detectors must be installed and linked with emergency ventilation and sprinkler systems.

Protective equipment: In the computer room, emergency equipment such as gas masks, goggles and protective clothing must be provided.

Safety valve and pressure relief: Pressure vessels must be equipped with safety valves, and the pressure relief pipes should be directed to an outdoor safe area.

Strict regulations: The design and construction must comply with the mandatory standards such as the "Cold Storage Design Code" (GB50072) and the "Construction and Acceptance Specifications for Ammonia Refrigeration System Installation" issued by the state.

Professional operation: Operators must hold relevant certificates and undergo regular safety training.

Main application fields

Food industry: Freezing and refrigeration of meat, seafood, fruits and vegetables; dairy product processing; beer brewing.

Chemical Engineering and Pharmacy: Process cooling, low-temperature reactions, gas liquefaction.

Logistics and warehousing: Large-scale cold chain logistics centers, high-temperature cold storage facilities.

Ice and snow venues: artificial ice rink, ski resort.

Others: Central air conditioning (area cooling), military research and development, etc.

Development Trends

Reduction and miniaturization of ammonia: By optimizing design (such as using plate heat exchangers) and through the use of refrigerants like carbon dioxide in a cascade system, the amount of ammonia in the system is reduced, expanding its application in near-commercial areas such as supermarkets and convenience stores.

Automation and Intelligence: Extensive use of PLC and IoT technologies to achieve remote monitoring, fault diagnosis, energy efficiency management, and predictive maintenance.

System integration optimization: Promote efficient screw compressors and heat recovery technology (recovering condensation heat to produce hot water), enhancing overall energy efficiency.

Safety standards are continuously improving: Regulations and standards are becoming increasingly strict, driving towards safer and more reliable designs and technological applications.

Summary

The ammonia refrigeration system is the backbone of industrial refrigeration, providing support for the extensive cold chain and basic industries with its outstanding energy efficiency and environmental-friendly features. However, "efficiency and risks coexist" is its most notable characteristic. The development of modern ammonia refrigeration technology is moving towards the direction of "greater safety, greater environmental friendliness, and greater intelligence", and especially the ammonia/CO2 cascade system is becoming the recognized gold standard in the industry.

Post time: Jan-06-2026