What is Scraped Surface Heat Exchanger?

Scraped Surface heat exchanger: Principle, application and future development

The scraped surface heat exchanger is a kind of efficient heat exchange equipment, which plays an important role in food, chemical, pharmaceutical and other industries. Through unique mechanical structure and operation mode, this kind of heat exchanger solves the problem of traditional heat exchanger in dealing with high viscosity and easy to scale materials. This paper will comprehensively analyze the scraper heat exchanger, an important industrial equipment, from the aspects of working principle, structural characteristics, application fields and future development trends.

First, the working principle and structure of scraped surface heat exchanger

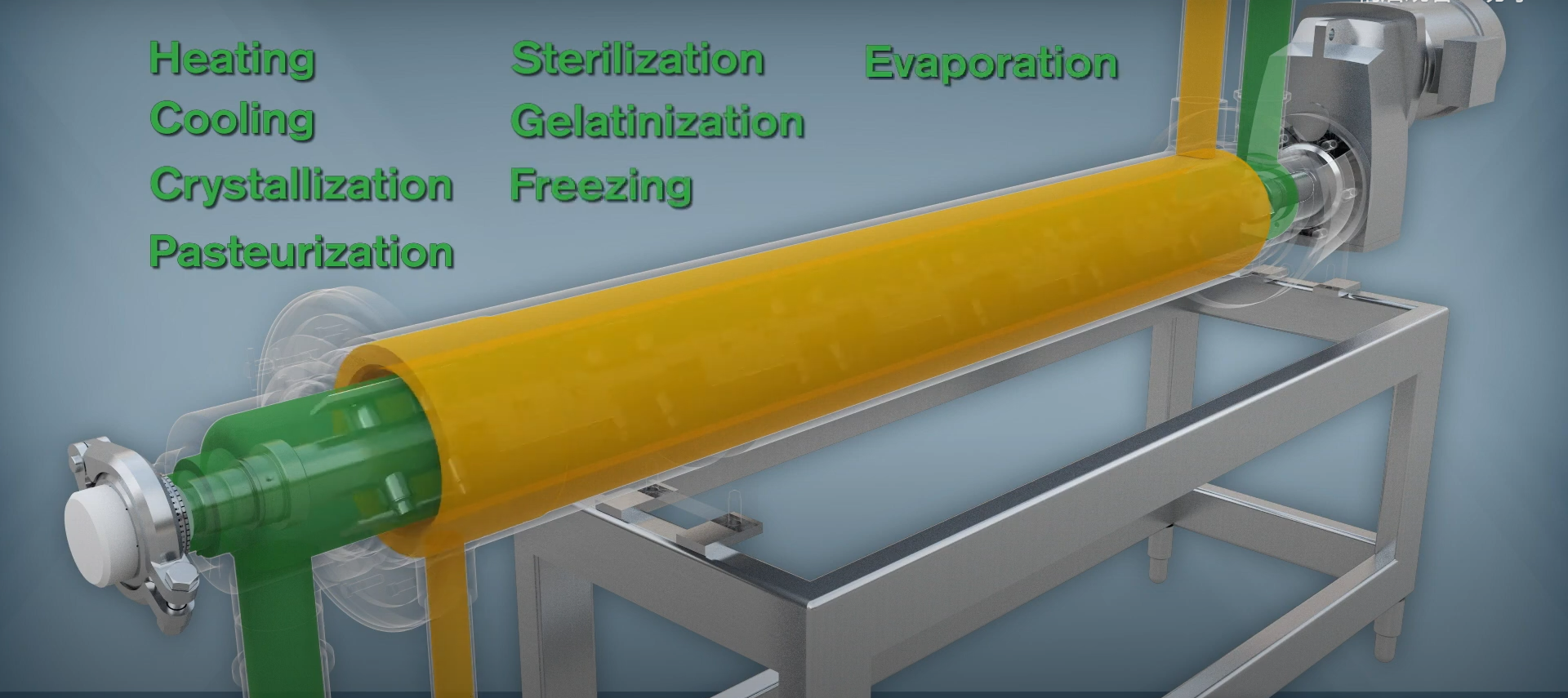

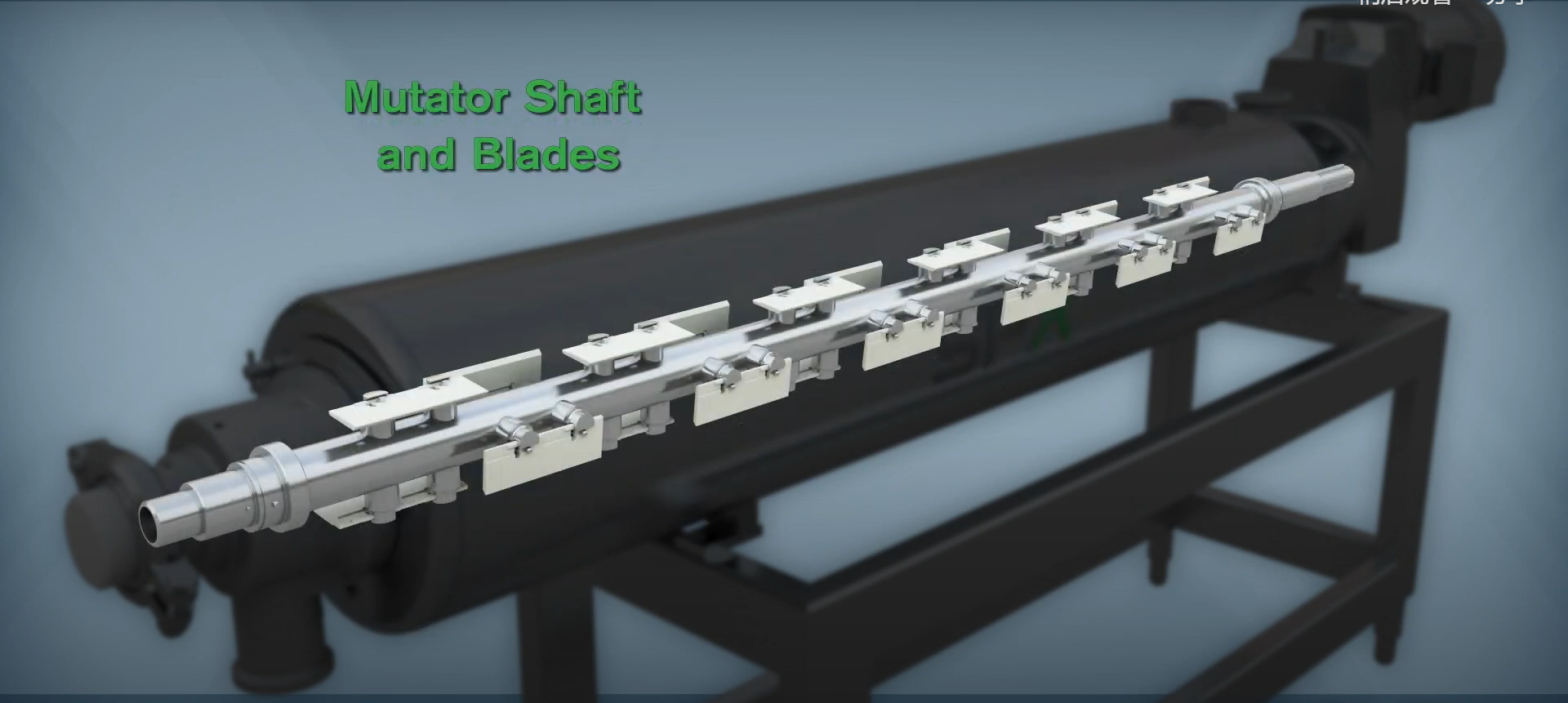

The core working principle of the scraped surface heat exchanger is to continuously scrape the heat exchange surface by rotating the scraper to achieve efficient heat transfer. The basic structure includes cylindrical heat exchanger body, rotating shaft, scraper assembly, driving device and sealing system. The heat exchanger body is usually double-layer structure, and the heating or cooling medium is passed into the middle. The rotating shaft is equipped with a plurality of scrapers, which are close to the inner wall of the cylinder under the action of centrifugal force and continuously scrape the heat transfer surface with the rotation of the shaft.

During the working process, the material to be treated enters the heat exchanger from the upper part and flows down the inner wall of the cylinder under the action of gravity. The rotating scraper not only plays the role of mixing, but more importantly, constantly updates the material film on the heat transfer surface to prevent the material from coking or scaling on the high temperature surface. This dynamic film renewal mechanism allows scraped surface heat exchangers to achieve extremely high heat transfer efficiency, often up to 3-5 times that of conventional heat exchangers.

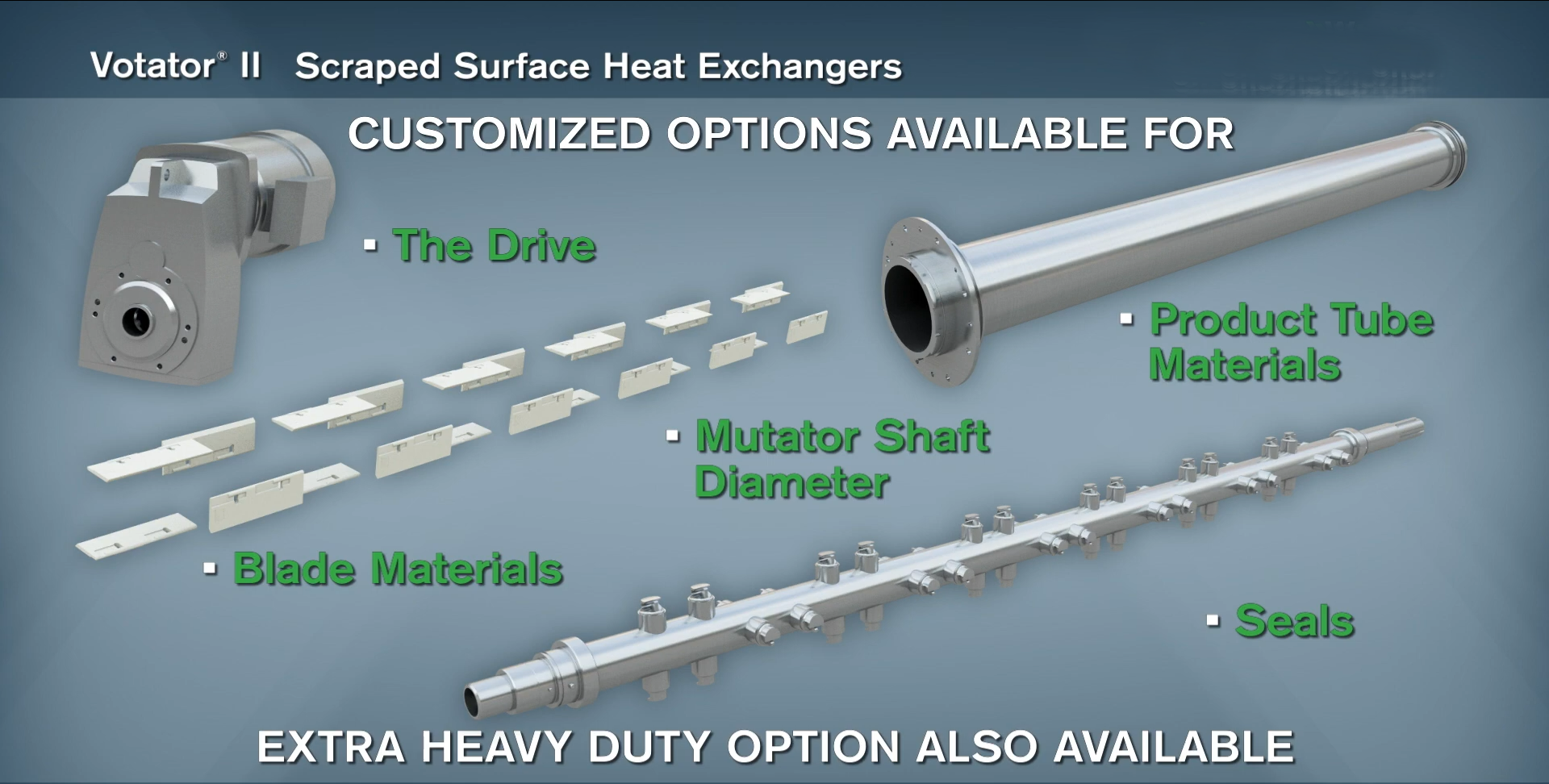

The key component of the scraped surface heat exchanger is the scraper system, whose design directly affects the performance of the equipment. Modern scraped surface heat exchangers mostly use adjustable scraper, through the spring or centrifugal force to adjust the contact pressure between the scraper and the cylinder wall, not only to ensure a good scraping effect, but also to avoid excessive wear. The sealing system is also an important part, both to prevent material leakage, but also to ensure the smooth operation of the rotating shaft.

Second, the technical advantages and limitations of scraped surface heat exchanger

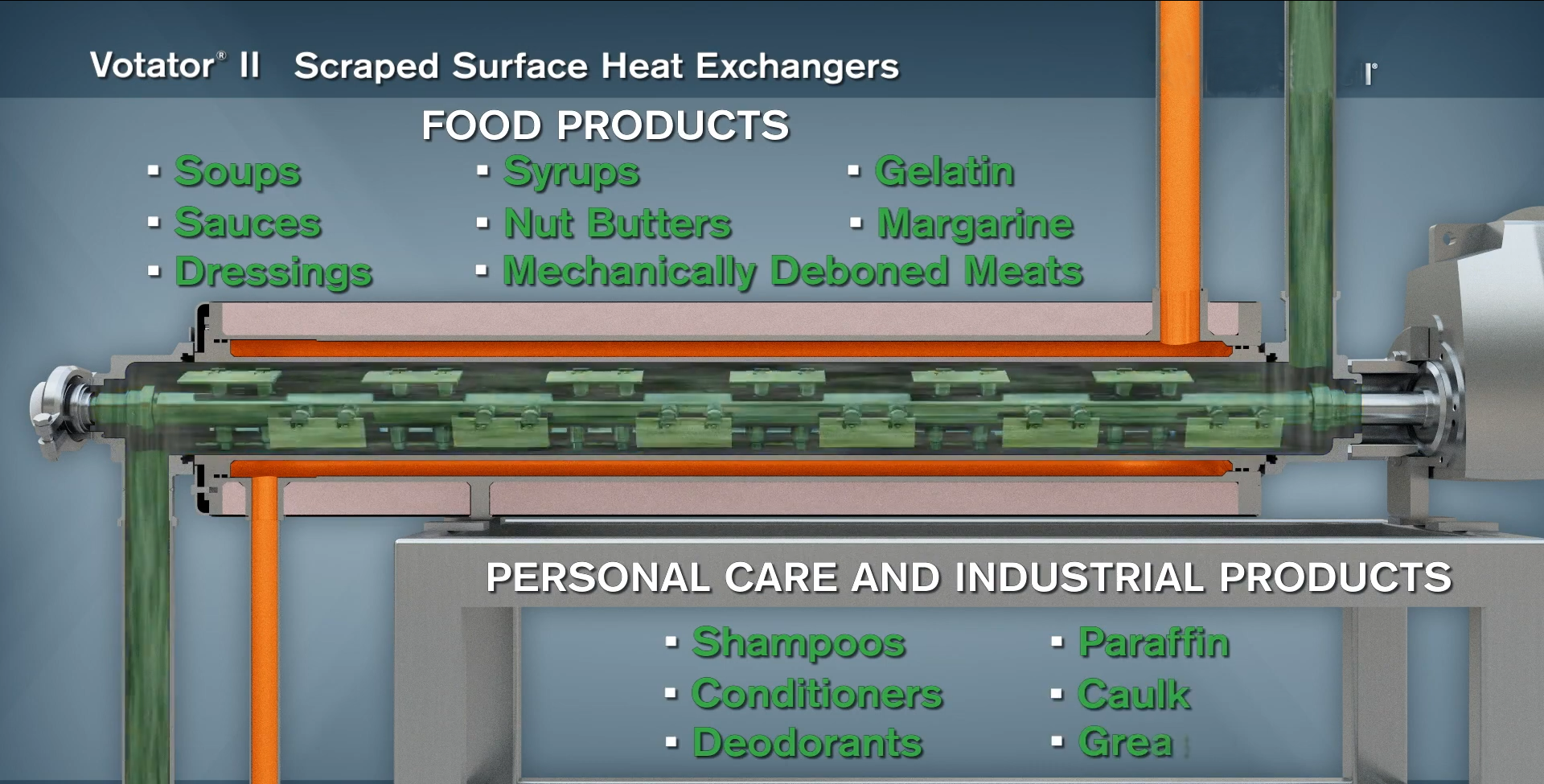

The most significant advantage of a scraper heat exchanger is its ability to handle highly viscous, heat-sensitive materials. In the field of food processing, such as the production of puff pastry margarine, chocolate, jam, cheese and other products, the traditional heat exchanger is difficult to meet the process requirements, and the scraper heat exchanger can perfectly solve these problems. Its heat transfer coefficient can reach 2000-5000W/(m²·K), much higher than the ordinary shell and tube heat exchanger.

When dealing with materials that are easy to scale, the advantages of the scraper heat exchanger are more obvious. In the petrochemical industry, heavy oil, asphalt and other materials are easy to coking on the heat transfer surface during the heating process, and traditional heat exchangers need frequent downtime for cleaning. The scraper heat exchanger through the continuous scraping effect, effectively prevent the coking phenomenon, greatly extend the continuous running time.

However, scraped surface heat exchangers also have some limitations. The first is the high cost of equipment, due to its complex mechanical structure and precision processing requirements, the initial investment is much larger than ordinary heat exchangers. Secondly, the maintenance cost is higher, and the scraper and seal are vulnerable parts and need to be replaced regularly. In addition, when dealing with low-viscosity materials, its advantages are not obvious, but may increase energy consumption due to mechanical mixing.

Third, the application field and future development of scraped surface heat exchanger

In the food industry, scraped surface heat exchangers are widely used in chocolate tempering, jam sterilization, butter crystallization and other processes. For example, in the production of chocolate, the material needs to be precisely controlled within a specific temperature range for temperature control treatment, and the scraper heat exchanger can achieve accurate temperature control and uniform heat exchange to ensure product quality.

In the field of chemical industry, scraped surface heat exchangers are mainly used in polymer production, heavy oil heating and other processes. In polymer production, the viscosity of the material changes with the reaction process, which is difficult to adapt to the traditional heat exchanger, but the scraper heat exchanger can always maintain efficient heat transfer. In the process of petroleum refining, the scraper heat exchanger is used to heat heavy oil, asphalt and other materials, which solves the coking problem.

In the future, the development of scraped surface heat exchangers will develop in the direction of intelligence, high efficiency and multi-function. In terms of intelligence, more sensors and control systems will be integrated to achieve real-time monitoring and automatic adjustment of operating parameters. The development of materials science will bring new materials that are more wear-resistant and corrosion-resistant and extend the service life of equipment. In addition, modular design will become a trend to facilitate the maintenance and upgrade of equipment.

As a kind of efficient heat exchange equipment, scraper heat exchanger plays an irreplaceable role in modern industrial production. With the continuous progress of technology, its application field will be further expanded, and its performance will continue to improve. In the future, the scraper heat exchanger will make greater contributions to energy saving and emission reduction, improve production efficiency, and provide strong support for the sustainable development of industrial production.

Post time: Feb-26-2025