Chinese Professional Margarine Tube Filling Machine - Margarine Can Filling Machine China Manufacturer – Shipu

Chinese Professional Margarine Tube Filling Machine - Margarine Can Filling Machine China Manufacturer – Shipu Detail:

Equipment Description

Can Filling Machine

Can Seamer

Apply to all kinds of food, cosmetic, medicine, veterinary medicine, pesticide, lubricating oil industry product filling. Auto four filling heading line is designed for cream, lotion, ointment, viscous liquid etc.

Filling head is equipped with special blowout preventer to prevent product dripping down.

Auto controlled by PLC with human-machine interface, full closed filling, high measuring accuracy, big filling range, compact structure, smooth operation.

Accurate level sensor, automatic filling materials, atmospheric fixed channel parameters, help you finish filling operation precise.

Specially design of integral lifting mechanism and unique. Convenient adjust, can satisfy various specifications of the container. Different from the traditional way of lifting, pipe bending and prolong filling time too.

Photoelectric sensor and pneumatic door control and lack of bottles, automatic protection.

Pneumatic valves, efficient and safe. Each channel can be independent regulation and cleaning.

It’s suitable for all kinds of rule shape bottle. Easy to clean, conveniently and speed quickly.

Contact with filling material is 316L stainless steel. Other part is SUS304 and aluminum alloy.

The main electrical components are imported, the machine beautiful and elegant, In accordance with GMP requirements.

Technical Specification

- Voltage: AC220 50HZ

- Power: 3KW

- Filling volume: 500-5000ML(Auto adjusted by touch screen )

- Accuracy: ±0.5%

- Speed: 0-50 bottles/min

- Air source: 0.4~0.8MPa

- Machine noise: ≤70dB

- Leakage proof nozzle design is adopt the product leakage when filling.

- Material: Contact with filling material part stainless steel 316L, the machine is 304 stainless steel and aluminum.

- Machine size:2200×1000×2200mm)L*W*H

- Weight: Around 680Kg

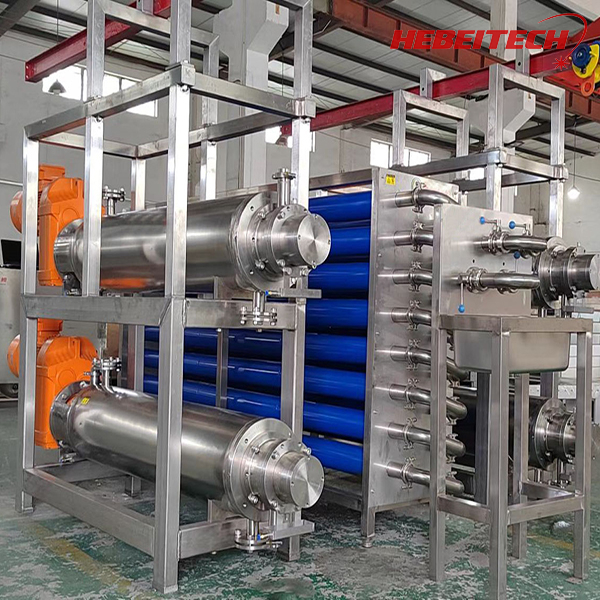

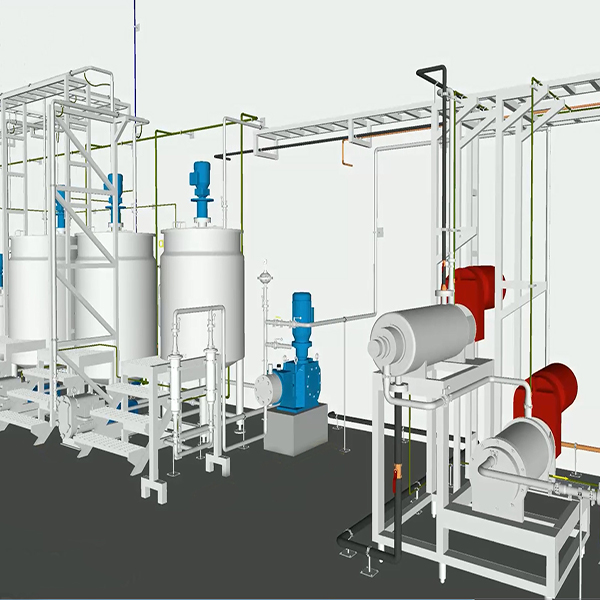

Equipment Picture

Can Filling Machine

Can Seamer

Electronics Configuration

| No. | Name | QTY | Brand | Country |

| 1 | Frequency converter | 1PC | Mitsubishi | Japan |

| 2 | PLC control system | 1PC | Siemens | Geman |

| 3 | Touch screen | 1PC | Siemens | Geman |

| 4 | Main electric components | 1PC | Schneider | French |

| 5 | Master cylinder | 6Pcs | AirTAC | Taiwan |

| 6 | Filling nozzle lifting cylinder | 6Pcs | AirTAC | Taiwan |

| 7 | Pneumatic element | 1Pc | AirTAC | Taiwan |

| 8 | Motor | 1 | TECO | Taiwan |

| 9 | Automatic feeding pump suction | 1Pc |

Site Commissioning

Product detail pictures:

Related Product Guide:

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for Chinese Professional Margarine Tube Filling Machine - Margarine Can Filling Machine China Manufacturer – Shipu , The product will supply to all over the world, such as: Italy, Namibia, Johannesburg, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.