Custard Sauce Production Line

Custard Sauce Production Line

Custard Sauce Production Line

Production Video: https://www.youtube.com/watch?v=AkAcycJx0pI

A custard sauce production line involves a series of automated and semi-automated processes to manufacture custard sauce efficiently, consistently, and hygienically. Below is a detailed breakdown of the typical stages in a custard sauce production line:

1. Ingredient Handling & Preparation

- Milk Reception & Storage

- Raw milk is received, tested for quality, and stored in refrigerated silos.

- Alternative: Reconstituted milk powder + water (for longer shelf life).

- Sugar & Sweetener Handling

- Sugar, corn syrup, or alternative sweeteners are weighed and dissolved.

- Egg & Egg Powder Processing

- Liquid eggs (pasteurized) or egg powder is mixed with water.

- Starch & Stabilizers

- Cornstarch, modified starch, or thickeners (e.g., carrageenan) are pre-mixed to prevent clumping.

- Flavorings & Additives

- Vanilla, caramel, or other flavors, along with preservatives (if needed), are prepared.

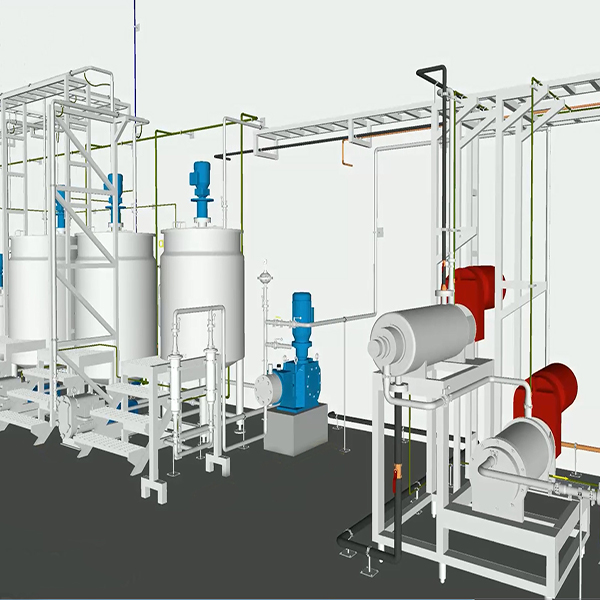

2. Mixing & Blending

- Batch or Continuous Mixing

- Ingredients are combined in a high-shear mixer or premix tank under controlled temperatures (to avoid premature thickening).

- Homogenization may be applied for smooth texture.

3. Cooking & Pasteurization

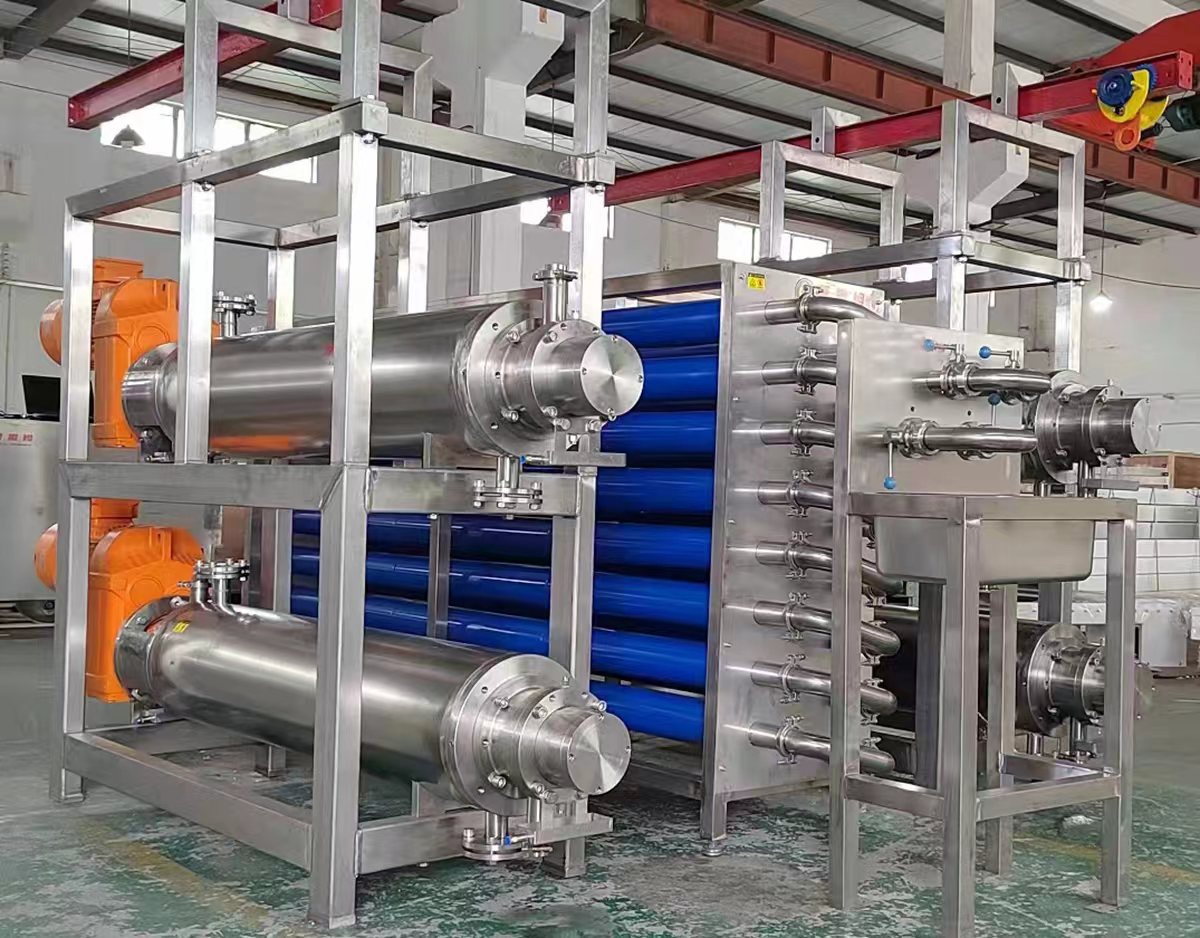

- Continuous Cooking (Scraped Surface Heat Exchanger)

- The mixture is heated to 75–85°C (167–185°F) to activate starch gelatinization and thicken the sauce.

- Pasteurization (HTST or Batch)

- High-Temperature Short-Time (HTST) at 72°C (161°F) for 15-20 sec or batch pasteurization to ensure microbial safety.

- Cooling Phase

- Rapid cooling to 4–10°C (39–50°F) to stop further cooking and maintain texture.

4. Homogenization (Optional)

- High-Pressure Homogenizer

- Used for ultra-smooth texture (prevents graininess).

5. Filling & Packaging

- Automatic Filling Machines

- Pouch filling (for retail) or bulk filling (for foodservice).

- Aseptic filling (for long shelf life) or hot-fill (for ambient storage).

- Packaging Formats:

- Plastic bottles, cartons, pouches, or cans.

- Nitrogen flushing may be used to extend shelf life.

6. Cooling & Storage

- Blast Chilling (if required)

- For refrigerated custard, rapid cooling to 4°C (39°F).

- Cold Storage

- Stored at 4°C (39°F) for fresh custard or ambient for UHT-treated products.

7. Quality Control & Testing

- Viscosity Checks (using viscometers).

- pH Monitoring (target: ~6.0–6.5).

- Microbiological Testing (total plate count, yeast/mold).

- Sensory Evaluation (taste, texture, color).

Key Equipment in Custard Sauce Production Line

- Storage Tanks (for milk, liquid ingredients).

- Weighing & Dosing Systems.

- High-Shear Mixers & Premix Tanks.

- Pasteurizer (HTST or Batch).

- Scraped Surface Heat Exchanger (for cooking).

- Homogenizer (optional).

- Filling Machines (piston, volumetric, or aseptic).

- Cooling Tunnels.

- Packaging Machines (sealing, labeling).

Types of Custard Sauce Produced

- Refrigerated Custard (short shelf life, fresh taste).

- UHT Custard (long shelf life, sterilized).

- Powdered Custard Mix (for reconstitution).

Automation & Efficiency

- PLC Control Systems for precise temperature and mixing control.

- CIP (Clean-in-Place) Systems for hygiene.

Site Commissioning

Write your message here and send it to us