Hot sale Sheet Margarine Packing Machine - SS316 Food Grade Emulsification Tank Homogenizer China Manufacturer – Shipu

Hot sale Sheet Margarine Packing Machine - SS316 Food Grade Emulsification Tank Homogenizer China Manufacturer – Shipu Detail:

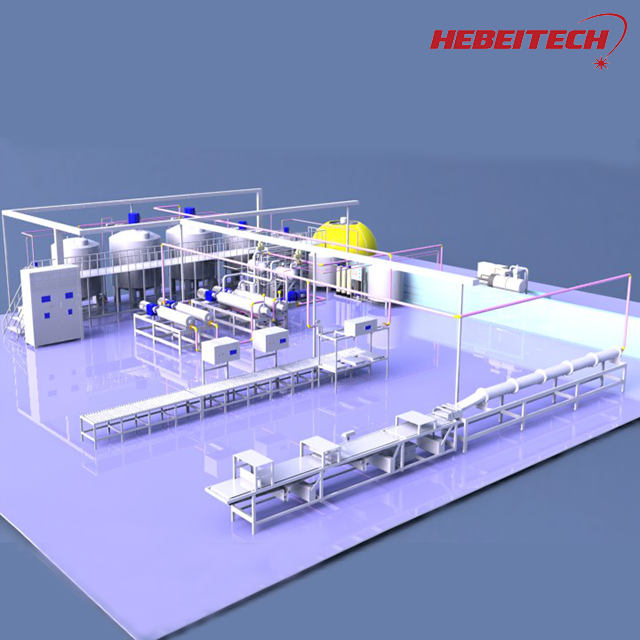

Sketch map

Description

The tank area includes tanks of oil tank, water phase tank, additives tank, emulsification tank (homogenizer), standby mixing tank and etc. All tanks are SS316L material for food grade, and meet the GMP standard.

Main Feature

The tanks are also used for produce puff pastry margarine, shortening, shampoo, bath shower gel, liquid soap, dish washing, hand washing, lubricating oil etc.

High speed disperser. might mixing and disperse viscously, solid and liquid etc. various kind of raw material will be dissolve which is such as AES, AESA, LSA, during liquid production which can save energy consumption and shorten production the and shorten production period

Main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed

Finished products can be discharged by valve or match a screw pump.

Technical spec.

| Item | Description | Remark |

| Volume | Full volume: 3250L, Working capacity:3000L | Loading coefficient 0.8 |

| Heating | Jacket is Electric heating, power: 9KW*2 | |

| Structure | 3 layers, Caldron, heating with keep warming system, unilateral cover on the pot, butterfly type sealing head at the bottom, with scraping the wall mixing, with pure water inlet/AES feeding port/alkali liquor inlet; | |

| Material | Internal layer: SUS316L, thickness: 8mm | |

| Middle layer: SUS304, thickness:8mm | Quality certificate | |

| External layer:SUS304, thickness:6mm | Insulation media: aluminum silicate | |

| Strut way | Stainless steel hang ear, support point distance is 600mm from the feeding hole | 4 pcs |

| Discharging way: | Bottom ball valve | DN65, hygiene level |

| Polishing level | Pot is internal and external sanitation polishing, fully meet the requirements of GMP hygiene standards; | GMP hygiene standards |

Equipment Picture

Site Commissioning

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for Hot sale Sheet Margarine Packing Machine - SS316 Food Grade Emulsification Tank Homogenizer China Manufacturer – Shipu , The product will supply to all over the world, such as: venezuela, Provence, Vietnam, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.