Margarine Crystallizer

China Scraped Surface Heat Exchanger & Votator Manufacturer and Supplier.Our company has China Scraped Surface Heat Exchanger & Votator on sale, welcome to contact us.

Production Video : https://www.youtube.com/watch?v=AkAcycJx0pI

Application in Margarine Production or Shortening Production

The following are their specific functions and principles:

1. Rapid Cooling and Crystallization Control

Function: Shortening needs to be rapidly cooled (quencher) to transform the oil from liquid to solid and form a stable β' crystal structure (fine and uniform crystal structure). This crystal structure endows shortening with good plasticity, extensibility, and texture.

Advantages of scraped surface heat exchangers:

The high-speed rotating scraper constantly scrapes the inner wall of the heat exchanger, preventing the formation of lumps or large crystals during cooling and ensuring fine and uniform crystals.

By precisely controlling the cooling rate (typically segmented cooling to 10-20°C), it promotes the formation of β' crystals rather than β crystals (coarse crystals, rough texture).

2. Efficient Heat Transfer and Temperature Uniformity

High-viscosity fluid handling: The viscosity of shortening increases sharply during cooling, and traditional heat exchangers are prone to reduced heat transfer efficiency or local overheating/overcooling.

Scraped surface design:

The scraper continuously stirs the material to ensure uniform heating/cooling and prevent temperature stratification.

The small temperature difference between the inner wall of the heat exchanger and the material results in a high heat transfer coefficient, suitable for rapid cooling of high-viscosity materials.

3. Prevention of Fouling and Continuous Production

Self-cleaning function: The scraper constantly removes residual oil from the inner wall, preventing fouling that could affect heat transfer efficiency, making it suitable for materials containing fat.

Continuous operation: Compared to batch cooling, scraped surface heat exchangers can achieve continuous feeding and discharging, improving production efficiency and being suitable for large-scale industrial production.

4. Process Flexibility

Adjustable parameters: By adjusting the scraper speed, cooling medium temperature (such as ammonia or cold water), or flow rate, the crystallization speed and final temperature can be flexibly controlled to adapt to different shortening formulas (such as hydrogenated vegetable oil, palm oil, etc.).

Synergy with other equipment: It is often used in conjunction with kneaders, further kneading after rapid cooling to improve texture.

5. Enhancing Product Quality

Avoiding defects: Rapid cooling and uniform shearing prevent shortening from having a sandy texture, layering, or oil separation.

Functional guarantee: The stable crystal structure formed directly affects the shortening's flakiness, emulsification, and extensibility during baking. Summary

Equiment Details

SPV series Scraped-surface heat exchanger utilities a modular design for vertical mounting on a wall or column and includes:

- Compact structure design

- Solid shaft connection (60mm) structure

- Durable blade material and technology

- High precision machining technology

- Solid heat transfer tube material and inner hole processing

- The heat transfer tube can be disassembled and replaced separately

- Gear motor drive - no couplings, belts or sheaves

- Concentric or eccentric shaft mounting

- GMP, 3A and ASME design standard; FDA optional

Working temperature : -30°C~ 200°C

Maximum working pressure

Material side : 3MPa (430psig), optional 6MPa (870psig)

Media side : 1.6 MPa (230psig),optional 4MPa (580 psig)

Cylinder

The inner cylinder diameter are 152 mm and 180mm

Capacity

The maximum flow rate is application specific and determined by the temperature program, the product properties and type of duty

Material

The heating surface is normally made of stainless steel, (SUS 316L), honed to a very high finish on the inner surface. For special applications different types of chrome coatings are available for the heating surface. The scraping blades are available in stainless steel and different types of plastic materials including a metal detectable type. The blade material and configuration is selected based on the application. Gaskets and O-rings are made of Viton, nitrile or Teflon. Suitable material will be selected for each application. Single seals, flushed (aseptic) seals are available, with material selection depending on the application

Technical Specification

| Model | Heat Exchanger Surface Area | Annular Space | Tube Length | Scraper Qty | Dimension | Power | Max. Pressure | Main Shaft Speed |

| Unit | M2 | mm | mm | pc | mm | kw | Mpa | rpm |

| SPV18-220 | 1.24 | 10-40 | 2200 | 16 | 3350*560*1325 | 15 or 18.5 | 3 or 6 | 0-358 |

| SPV18-200 | 1.13 | 10-40 | 2000 | 16 | 3150*560*1325 | 11 or 15 | 3 or 6 | 0-358 |

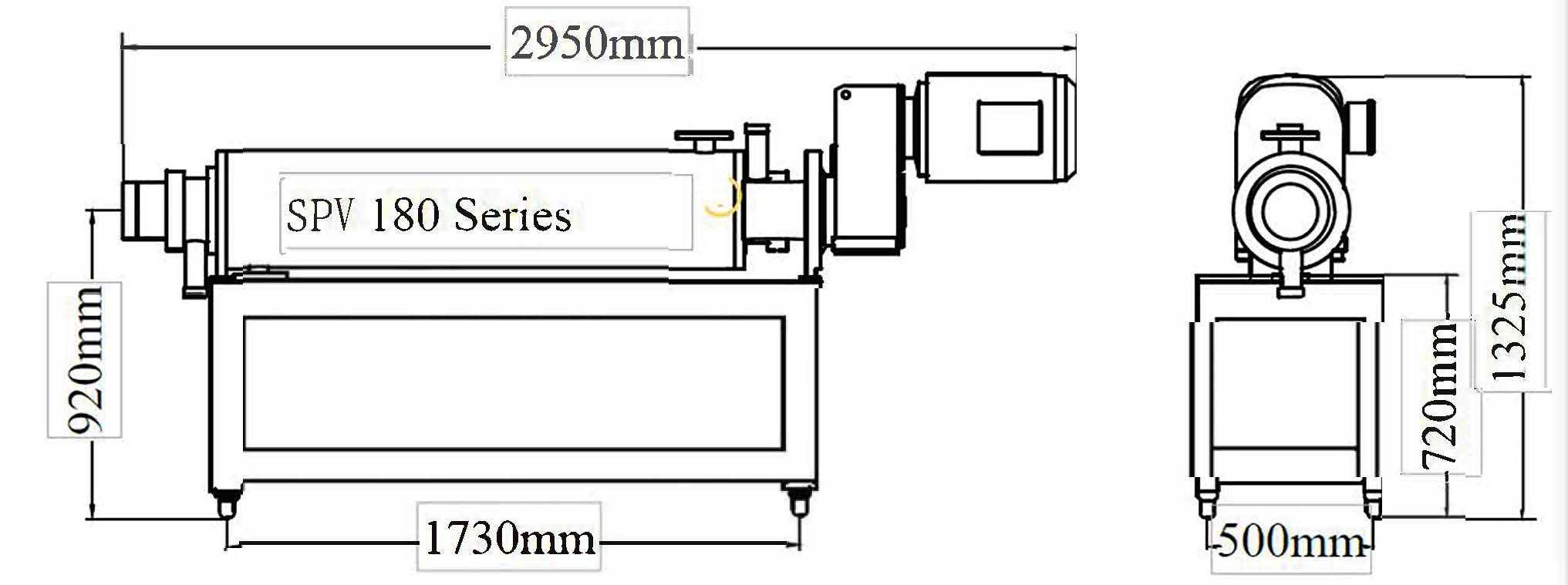

| SPV18-180 | 1 | 10-40 | 1800 | 16 | 2950*560*1325 | 7.5 or 11 | 3 or 6 | 0-340 |

| SPV15-220 | 1.1 | 11-26 | 2200 | 16 | 3350*560*1325 | 15 or 18.5 | 3 or 6 | 0-358 |

| SPV15-200 | 1 | 11-26 | 2000 | 16 | 3150*560*1325 | 11 or 15 | 3 or 6 | 0-358 |

| SPV15-180 | 0.84 | 11-26 | 1800 | 16 | 2950*560*1325 | 7.5 or 11 | 3 or 6 | 0-340 |

| SPV18-160 | 0.7 | 11-26 | 1600 | 12 | 2750*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPV15-140 | 0.5 | 11-26 | 1400 | 10 | 2550*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPV15-120 | 0.4 | 11-26 | 1200 | 8 | 2350*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPV15-100 | 0.3 | 11-26 | 1000 | 8 | 2150*560*1325 | 5.5 | 3 or 6 | 0-340 |

| SPV15-80 | 0.2 | 11-26 | 800 | 4 | 1950*560*1325 | 4 | 3 or 6 | 0-340 |

| SPV-Lab | 0.08 | 7-10 | 400 | 2 | 1280*200*300 | 3 | 3 or 6 | 0-1000 |

| SPT-Max | 4.5 | 50 | 1500 | 48 | 1500*1200*2450 | 15 | 2 | 0-200 |

| Note: High Pressure model can provide pressure environment up to 8MPa(1160PSI)with a motor power of 22KW(30HP) | ||||||||

Equipment Drawing

Site Commissioning