Renewable Design for Ketchup Pasteurization And Cooling System – Block Margarine Packaging Line China Manufacturer – Shipu

Renewable Design for Ketchup Pasteurization And Cooling System – Block Margarine Packaging Line China Manufacturer – Shipu Detail:

Equipment Description

Technical parameters of block margarine packaging machine

Main functions: block margarine packaging and cartonning.

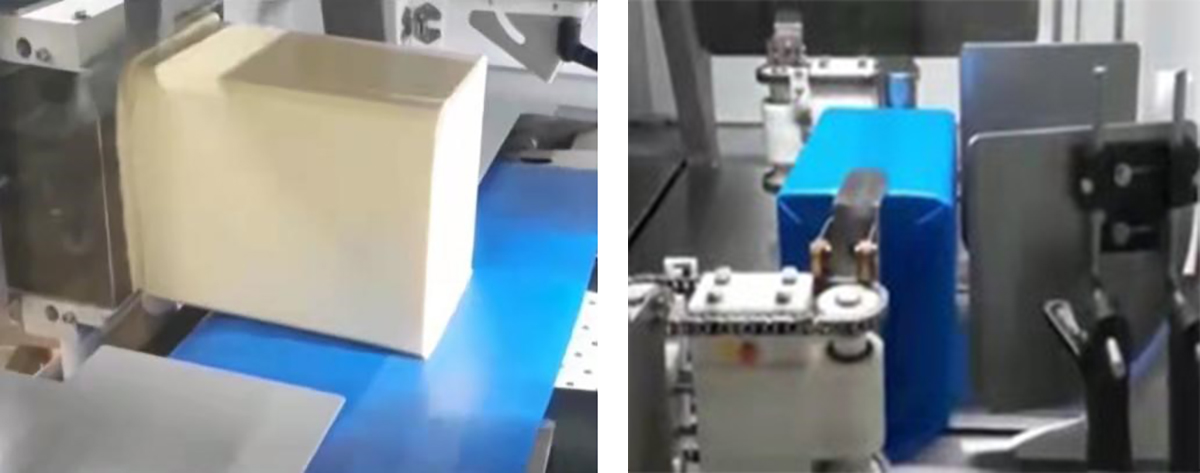

The oil paper is used as the outer packaging material. According to the outer size of the block margarine, the block margarine is automatically packaged into a four-sided closed state through the block margarine packaging equipment.

There is an unpacking machine in the front, which can automatically pack through the central lifting platform, and an automatic sealing machine in the back.

Scope of application: block margarine packaging, block shortening packaging and other similar foods packaging

Applicable range of package size: 190mm < length < 220mm; 100mm < width < 150mm; 90mm < height < 120mm;

Applicable packaging raw materials: packaging oil paper

Packing method of equipment: fold and pack the equipment with oil paper on all sides

Power consumption of equipment and applicable power supply and gas supply requirements:

power:4KW

Equipment power supply requirements: 380V three-phase five wire system

Compressed air requirements:>0.6MPA

Requirements for installation area of equipment: 12000(L)×12000(W)×2500mm(H)

Site requirements:5000(L)×15000(W)×3500mm(H)

Working Steps

Block margarine cutting — > film feeding — > cutting — > film lifting — > left and right lamination — > upper left and right folding — > block margarine rotation — > left and right front folding — > left and right back folding — > bottom left and right folding — > forming and conveying — > block margarine arrangement

Cardboard input — > unpacking machine — > carton forming — > carton conveying — > carton positioning — > manipulator positioning — > clamping block margarine — > extraction rise — > carton placement positioning — > completed

Carton positioning is loosened — > finished products are sent out — > sealing machine seals — > packaging is completed.

Site Commissioning

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Renewable Design for Ketchup Pasteurization And Cooling System – Block Margarine Packaging Line China Manufacturer – Shipu , The product will supply to all over the world, such as: Mexico, Serbia, Morocco, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!