Control System In Margarine Production Line

Description

Here’s a detailed breakdown of its role, components, and functions in margarine production.

1. Core Purpose of the Control system/System

The primary purpose is to automate, monitor, and control the entire production process to ensure:

- Consistent Product Quality: Uniform taste, texture, color, and melting properties every single batch.

- Production Efficiency: Maximize throughput and minimize waste and downtime.

- Recipe Management: Precisely execute different formulations for various product types (e.g., hard block margarine, soft tub, low-fat spreads).

- Safety: Monitor critical safety parameters (pressure, temperature) and manage emergency shutdowns.

- Data Tracking & Traceability: Record all process data for quality control and compliance.

2. Key Components of the Control System

A typical system consists of both hardware and software:

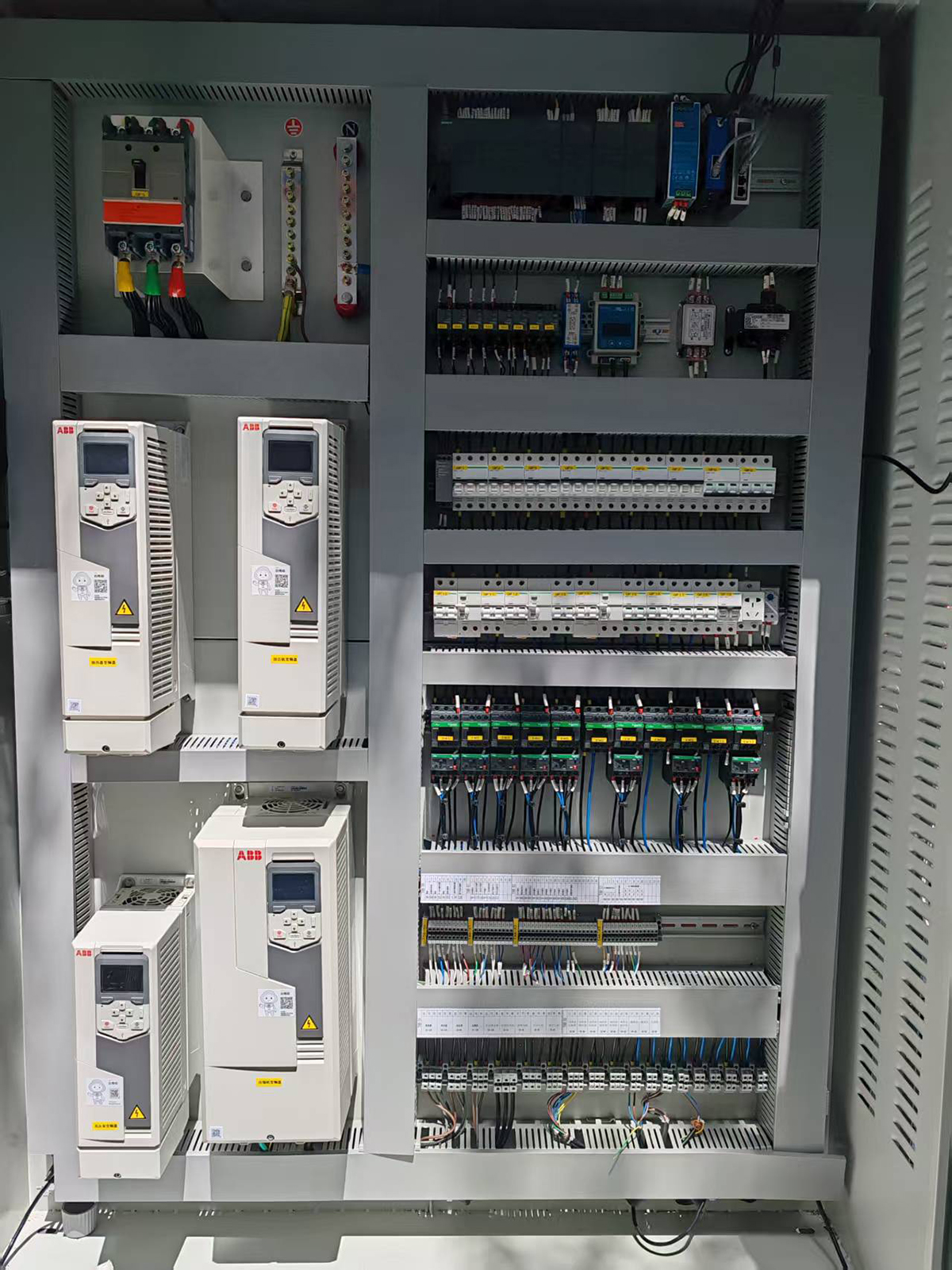

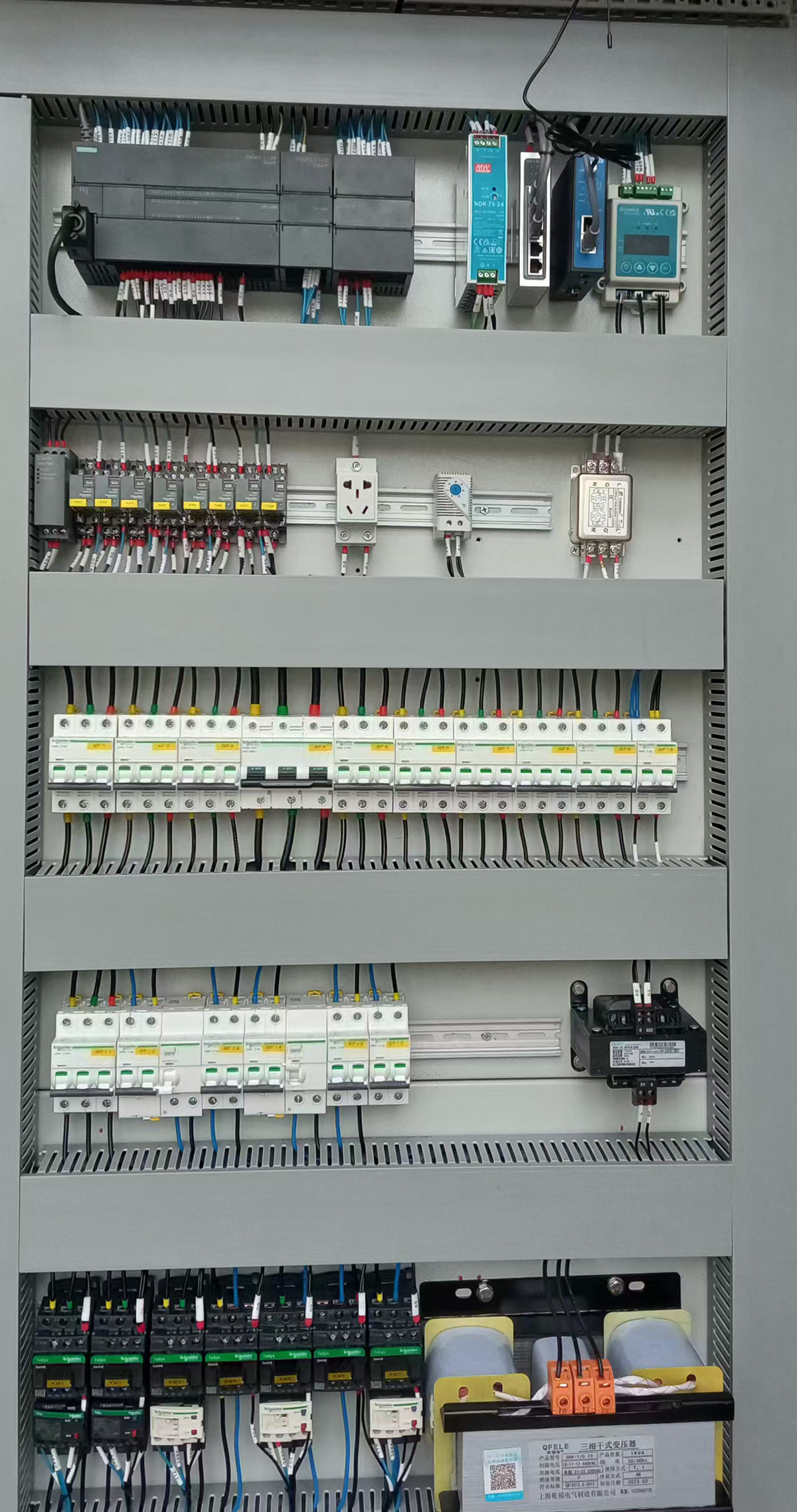

Hardware:

- PLC (Programmable Logic Controller): The physical "control system" or cabinet that houses the computer brain, input/output (I/O) modules, and communication cards.

- HMI (Human-Machine Interface): The touchscreen panel near the equipment where operators can monitor the process, view alarms, and make manual adjustments.

- Sensors & Instruments: These are the "eyes and ears" of the system, feeding data back to the PLC. Critical ones include:

- Temperature Sensors (RTDs, Thermocouples): On pasteurizers, chilling tubes, scraped surface heat exchangers, and resting tubes.

- Pressure Transmitters: On high-pressure pumps and lines.

- Flow Meters: To measure the precise quantity of oils, water, and additives.

- pH Probes: To monitor the water phase acidity.

- Level Sensors: In ingredient tanks and silos.

- Actuators & Drives: The "hands" of the system that execute commands from the PLC. This includes:

- Control Valves: To regulate the flow of ingredients, steam, and coolant.

- Variable Frequency Drives (VFDs): To control the speed of pumps, agitators, and the chilling unit's dasher motors.

- Motor Starters: For larger equipment like pumps and compressors.

Software:

- Control Logic: The program running on the PLC that makes decisions (e.g., "IF temperature is too high, THEN open coolant valve more").

- SCADA (Supervisory Control and Data Acquisition): A software system running on a central computer that provides a high-level overview of the entire plant. It collects data from all PLCs, displays trends, generates reports, and logs historical data.

3. How it Controls the Margarine Production Process

The control system manages each stage of production:

1. Ingredient Preparation & Dosing (Oil Phase & Water Phase):

- Function: Precisely controls the pumps and valves to blend the correct amounts of refined oils, emulsifiers, colorants (beta-carotene), and vitamins (Oil Phase) and water, salt, milk proteins, and preservatives (Water Phase).

- Control Action: The PLC receives flow meter data and adjusts control valves or VFDs on pumps to achieve the exact recipe ratios.

2. Emulsification:

- Function: Controls the emulsifier unit to create a stable water-in-oil emulsion.

- Control Action: Manages the agitator speed and ensures ingredients are held at a specific temperature.

3. Pasteurization:

- Function: Heats the emulsion to a specific temperature to kill any microorganisms.

- Control Action: The PLC uses a temperature sensor in the pasteurizer's outlet to modulate a steam control valve, maintaining a precise, pre-set temperature.

4. Chilling and Crystallization (The Votator™ / SSHE):

- This is the most critical control stage. The texture and spreadability of the final product are determined here.

- Function: Precisely controls the scraped surface heat exchangers (SSHEs) and resting tubes (pickers).Control Action: A complex loop of temperature, pressure, and flow control. The PLC constantly adjusts coolant valves and VFDs on the dasher motors based on sensor feedback.

- SSHEs: The PLC tightly regulates the ammonia or Freon coolant temperature and pressure. It also monitors and controls the speed of the mutator (scraper) shaft inside the tube. Speed is crucial for heat transfer and crystal formation.

- Resting Tubes (Pickers): Controls the flow rate and holding time to allow the fat crystals to form in the specific polymorphic form (β') that gives margarine its smooth, spreadable texture.

5. Working & Packaging:

- Function: For tub margarine, the soft product is simply pumped to filler machines. For block margarine, it may be worked further and then extruded.

- Control Action: Coordinates the speed of the filler with the output of the chilling line. Monitors package weight and manages the conveyor system.

4. Advanced Functions

Modern control systems offer more than just basic control:

- Recipe Management: Store hundreds of recipes. An operator can simply select "Tub Soft" or "Baking Block" on the HMI, and the system automatically sets all parameters (temperatures, speeds, flow rates).

- Trending & Historical Data: Track process variables over time. This is invaluable for troubleshooting issues (e.g., "Why did product texture change at 2:00 PM?") and for quality audits.

- Alarm Management: Immediately alert operators to problems (e.g., "Low Pressure in Ammonia Line," "High Temperature Alarm on SSHE #3").

- Batch Reporting & Traceability: Record all data for each production batch, creating a digital footprint for full traceability from raw material to finished product.

Summary

The "control system" in margarine production is a highly integrated automation system. It transforms a complex chemical and physical process involving precise temperature, shear, and crystallization control into a reliable, repeatable, and efficient operation, ensuring the final product on the supermarket shelf is always consistent.

Site Commissioning