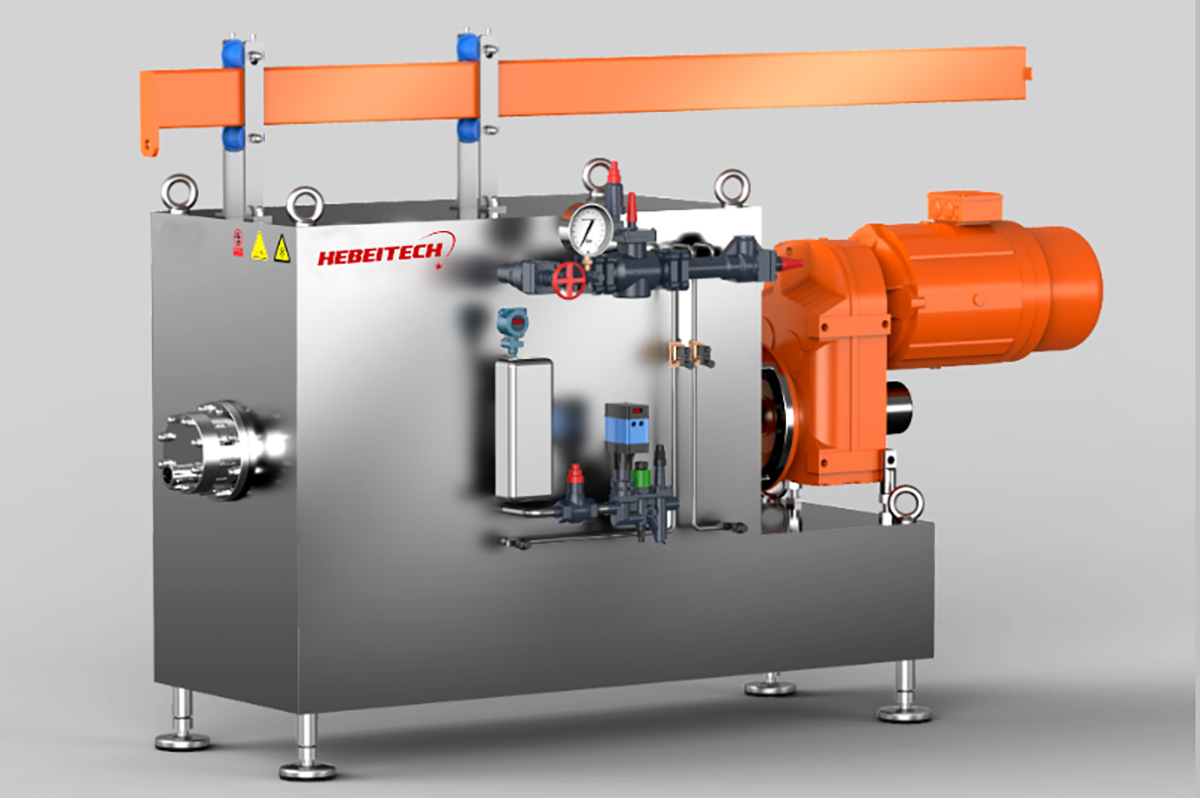

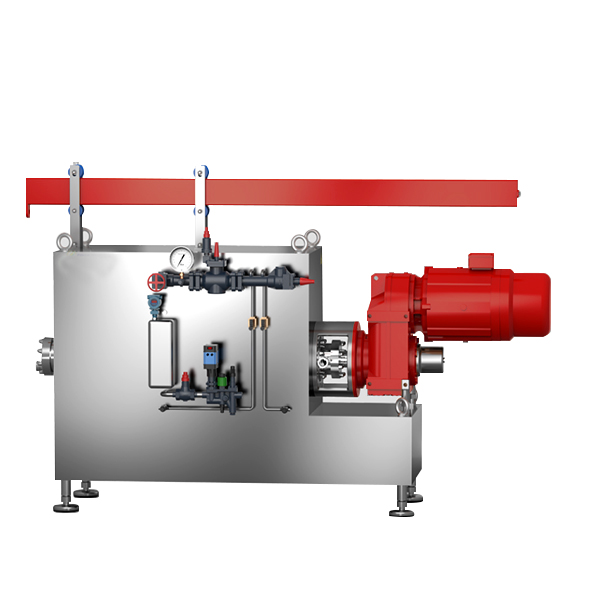

Cream Butter Production Line

Cream Butter Production Line

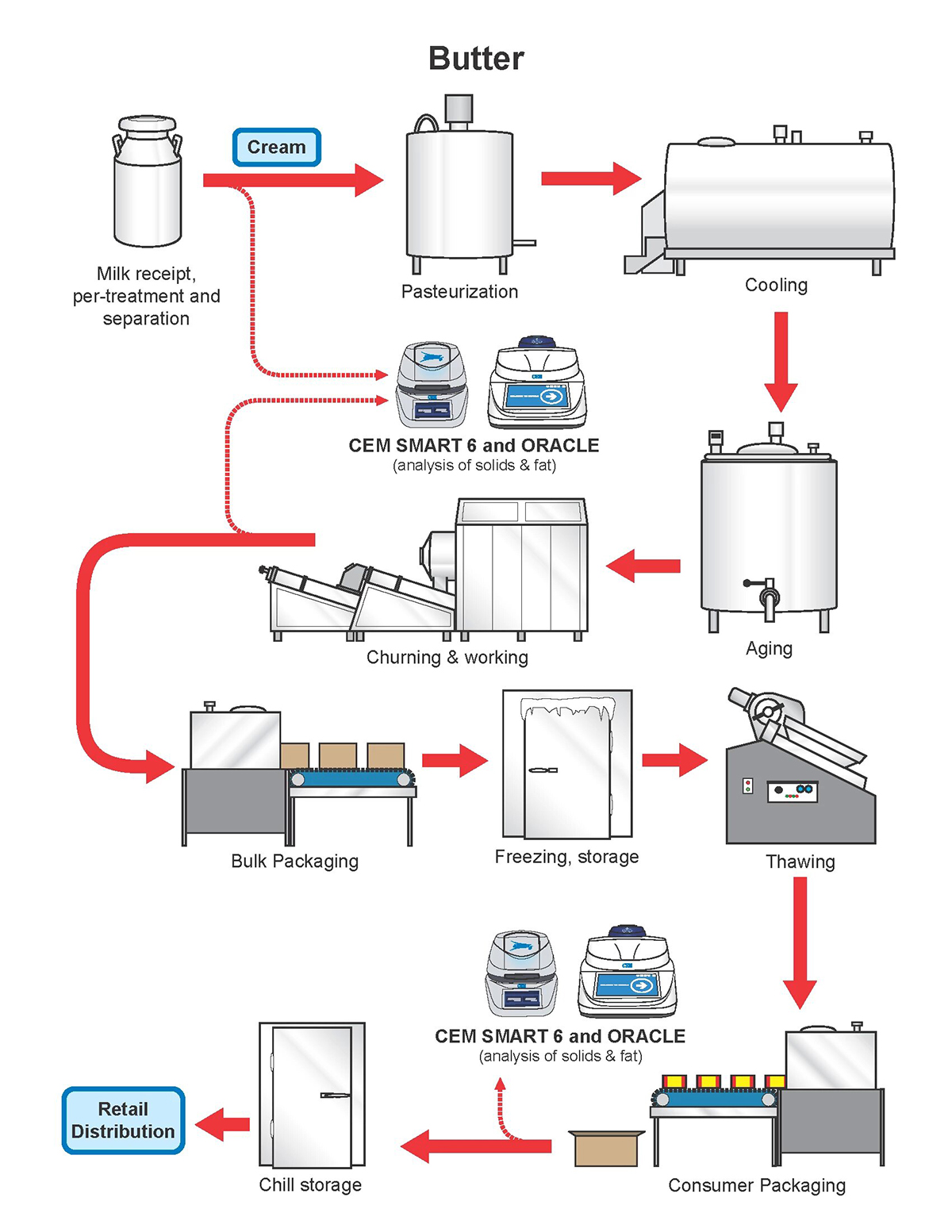

Summary of the Butter-Making Process:

Milk → Separation → Cream → Pasteurization → (Ripening for cultured) → Aging → CHURNING → Draining Buttermilk → Washing → Working → Packaging → Butter

The process can be broken down into three main stages: Cream Processing, Churning & Working, and Packaging & Storage.

1. Cream Processing: Preparing the Raw Material

This is the most critical stage for determining the final flavor and quality of the butter.

- Separation: Raw whole milk is first separated into cream and skim milk. This is done using a centrifugal separator that spins the milk at high speeds. The denser skim milk moves to the outside, while the lighter cream is collected from the center.

- Pasteurization: The cream is heated to a specific temperature (e.g., 85°C/185°F for 15-20 seconds) to destroy pathogenic bacteria and enzymes that could cause spoilage. This ensures safety and extends shelf life.

- Ripening (for Cultured Butter): This step is what differentiates sweet cream butter from cultured butter.Aging/Tempering: The cream is cooled and held at a low temperature (around 4-8°C or 40-46°F) for 8-12 hours. This "aging" process allows the fat crystals to harden, which is crucial for the fat to churn properly and yield a good volume of butter.

- Sweet Cream Butter: The pasteurized cream is cooled immediately and moved to the churn. This results in a milder, creamier flavor (the most common type in the US and UK).

- Cultured Butter: A lactic acid bacterial culture is added to the pasteurized cream. It is then incubated for several hours. The bacteria ferment the lactose (milk sugar) into lactic acid, giving the butter a richer, tangier, and more complex flavor (common in Europe).

2. Churning & Working: The Physical Transformation

This is the stage where the physical state of the cream changes dramatically.

- Churning: The cooled, aged cream is poured into a mechanical churn. Modern churns are large, rotating stainless steel drums or continuous churning machines.Draining Buttermilk: Once the butter grains have reached the size of small peas or wheat kernels, the churning stops. The buttermilk is drained off. (This is the "true" buttermilk, which is tangy and low in fat, unlike the cultured drink found in stores).

- The Science: As the cream is agitated, air is incorporated, forming foam. The fat globules, which are surrounded by a fragile phospholipid membrane, collide and their membranes rupture.

- The Result: The liquid fat inside the globules leaks out and begins to stick together, clumping into larger and larger grains of butterfat. This leaves behind a liquid called buttermilk.

- Washing: The butter grains are then washed with clean, cold water. This step removes any remaining buttermilk, which would cause the butter to spoil faster.

- Salting (Optional): Salt can be added for flavor and as a natural preservative. It is either added dry or as a brine and mixed in thoroughly.

- Working: The butter is then "worked" or kneaded. This is a mechanical process that ensures the water content is finely dispersed as tiny droplets throughout the fat phase (this is called an water-in-oil emulsion). It also gives the butter its final smooth, consistent texture and appearance.

3. Packaging and Storage

- Packaging: The finished butter is automatically cut and packaged into blocks, tubs, or rolls using parchment paper or foil wrappers to protect it from light and air, which can cause oxidation and rancidity.

- Storage: Butter is stored and transported refrigerated to maintain its solid structure and freshness. Because it is about 80% fat, it can also pick up off-flavors from other foods in the fridge, so airtight packaging is important.

Key Outputs of Butter Production:

- Butter: The primary product. By definition, butter must contain at least 80% milk fat. The remainder is water (about 16-18%) and milk solids (about 1-2%).

- Buttermilk: The by-product. Traditionally, this was the liquid left after churning. It is now often cultured separately after draining to create the cultured buttermilk beverage sold in stores.

Types of Butter:

- Sweet Cream Butter: Made from fresh, pasteurized cream. Mild flavor.

- Cultured Butter: Made from cream fermented with bacterial cultures. Tangy, "grown-up" flavor.

- Salted vs. Unsalted: Self-explanatory. Unsalted is often called "sweet butter."

- European-Style Butter: Has a higher fat content (82-86%) and is often cultured, resulting in a richer flavor and creamier texture, excellent for baking.

Write your message here and send it to us