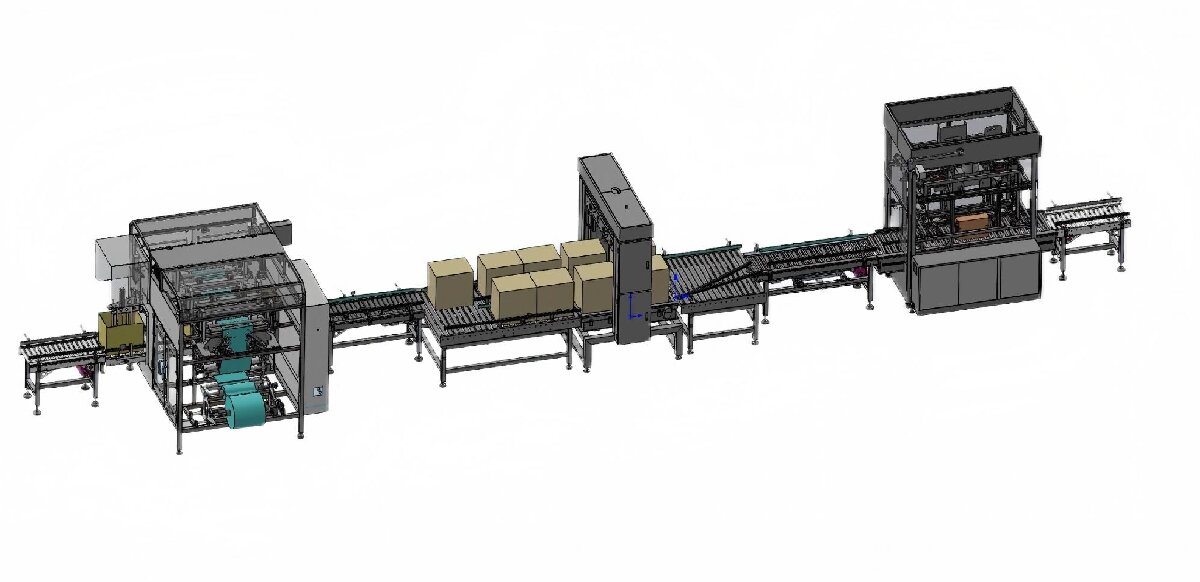

Margarine Bag-In-Box Filling Line

Description

Margarine filling machine (shortening filling machine)

This margarine filling machine (shortening filling machine) can be used for a variety of liquids with different viscosity, especially for all kinds of animal grease and margarine after quenching and kneading.

This margarine filling machine (shortening filling machine) can be used for a variety of liquids with different viscosity, especially for all kinds of animal grease and margarine after quenching and kneading.

Composition

The margarine filling machine (shortening filling machine) is composed of the front full-box conveyor belt, the split-track conveyor belt, the filling host machine, the combined conveyor belt and the rear full-box conveyor belt.

The front full-box conveyor belt will be accurately controlled by the photoelectric baffle, and the roller driven by the motor controlled by the converter will transport the carton to the lane conveyor belt at a timely and appropriate speed.

The sub-channel conveyor belt pushes the cartons delivered by the former full-box conveyor belt to the waiting position in two ways according to the filling requirements through the photoelectric pushing cylinder and the blocking cylinder. As long as the filling is finished, the cartons in the waiting position will start at the same time as the cartons in the filling position, and the cartons will be sent to the filling position.

The margarine filling machine (shortening filling machine) automatically senses whether there is a carton in the filling position to prevent leakage caused by mis-operation. Filling port according to the parameters set in advance alternate filling, and return valve interlock control, to ensure constant pipeline pressure.

Features:

² With automatic peeling function, automatic induction filling bucket;

² Interactive/independent, automatic/manual filling function;

² Set the required filling weight in the design range;

² Automatic control of fast and slow filling to prevent overflow;

² Adopt American Metler-Toledo sensor and high-precision weighing instrument.

² Convenient for CIP cleaning;

² Main technical parameters of four-head alternating filling machine

² Filling weight: 5-30 kg

² Production capacity: (according to the design beat, double head filling machine for 5-6 cases/minute, four head filling machine 10-12 cases/minute, six head filling machine 16-18 cases/minute,) 400-600 cases (barrels)/hour (20 kg per case, depending on the viscosity of the medium)

² Weighing error: 0.2%

² Liquid material inlet pressure: ≦0.6MPa

² Air source working pressure: commonly used air pressure 0.6Mpa, equipment with low pressure suspension function, when the air pressure is lower than the set value, the equipment will stop working

² Power supply: AC380V±10%

² The power of the whole machine is about 5kw

² Combined conveyor belt will combine the two filling boxes into one.

² The carton conveyed by the rear FCL conveyor belt will be sent to the next station at a uniform speed.

Flowchart process

Site Commissioning