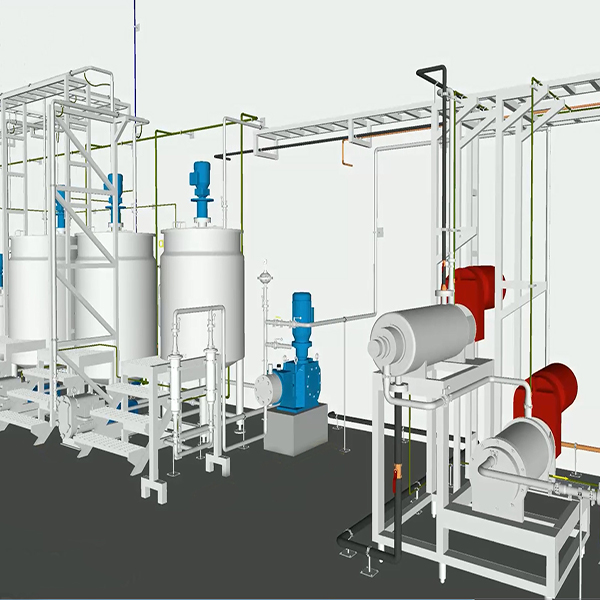

Small Scale Shortening Production Line

Small Scale Shortening Production Line

Small Scale Shortening Production Line

Equipment Video: https://www.youtube.com/watch?v=X-eQlbwOyjQ

A small scale shortening production line or skid-mounted shortening production line is a compact, modular, and pre-assembled system designed for the industrial production of shortening (a semi-solid fat used in baking, frying, and food processing). These skid-mounted systems are ideal for space efficiency, quick installation, and mobility, making them suitable for medium to large-scale food processing plants.

Key Components of a Skid-Mounted Shortening Production Line

1. Ingredient Handling & Preparation

² Oil/Fat Storage Tanks (for liquid oils like palm, soybean, or hydrogenated fats)

² Metering & Blending System – Precisely mixes oils with additives (emulsifiers, antioxidants, or flavorings).

² Heating/Melting Tanks – Ensures oils are at optimal temperature for processing.

2. Hydrogenation (Optional, for Hydrogenated Shortening)

² Hydrogenation Reactor – Converts liquid oils into semi-solid fats using hydrogen gas and a nickel catalyst.

² Gas Handling System – Controls hydrogen flow and pressure.

² Post-Hydrogenation Filtration – Removes catalyst residues.

3. Emulsification & Mixing

² High-Shear Mixer/Emulsifier – Ensures uniform texture and consistency.

² Scraped Surface Heat Exchanger (SSHE) – Cools and crystallizes the shortening for plasticity.

4. Crystallization & Tempering

² Crystallization Unit – Controls fat crystal formation for desired texture (β or β’ crystals).

² Tempering Tanks – Stabilizes the shortening before packaging.

5. Deodorization (For Neutral Flavor)

² Deodorizer (Steam Stripping) – Removes off-flavors and odors under vacuum.

6. Packaging & Storage

² Pumping & Filling System – For bulk (drums, totes) or retail packaging (tubs, cartons).

² Cooling Tunnel – Solidifies packaged shortening before storage.

Advantages of Small Scale Shortening Line /Skid-Mounted Shortening Lines

² Modular & Compact – Pre-assembled for easy installation and relocation.

² Faster Deployment – Reduced setup time compared to traditional fixed lines.

² Customizable – Adjustable for different types of shortening (all-purpose, bakery, frying).

² Hygienic Design – Made of food-grade stainless steel (SS304/SS316).

² Energy Efficient – Optimized heating/cooling systems reduce power consumption.

Types of Shortening Produced

² All-Purpose Shortening (for baking, frying)

² Bakery Shortening (for cakes, pastries, biscuits)

² Non-Hydrogenated Shortening (trans-fat-free alternatives)

² Specialty Shortenings (high-stability, emulsified, or flavored variants)

Production Capacity Options

|

Scale |

Capacity |

Suitable For |

|

Small-Scale |

100-200kg/h |

Startups, small bakeries, recipe design |

|

Medium-Scale |

500-2000kg/h |

Mid-sized food processors |

|

Large-Scale |

3-10tons/h |

Big Industrial manufacturers |

Considerations When Choosing a Skid-Mounted Line

² Raw Material Type (palm oil, soybean oil, hydrogenated fats)

² End-Product Requirements (texture, melting point, trans-fat content)

² Automation Level (manual, semi-auto, or fully automated PLC control)

² Regulatory Compliance (FDA, EU, Halal, Kosher certifications)

² After-Sales Support (maintenance, spare parts availability)

Conclusion

A skid-mounted shortening production line offers a flexible, efficient, and cost-effective solution for producing high-quality shortening. It is ideal for food manufacturers looking for a scalable, plug-and-play system with minimal installation downtime.

Site Commissioning