Super Votator in Butter Production & Margarine Production

Function & Advantage of Super Votator

Role in Butter Production

Butter is a water-in-oil emulsion (~80% fat) that requires controlled cooling and crystallization for optimal texture and spreadability.

Key Applications:

Rapid Cooling & Fat Crystallization

The votator quickly cools cream or melted butter from ~40°C to 10–15°C, promoting the formation of β' crystals (small, stable fat crystals that ensure smooth texture).

High shear prevents large crystal formation, avoiding graininess.

Working/Texturizing

Some systems integrate the votator with a pin worker or kneading unit to further refine butter texture, improving spreadability and mouthfeel.

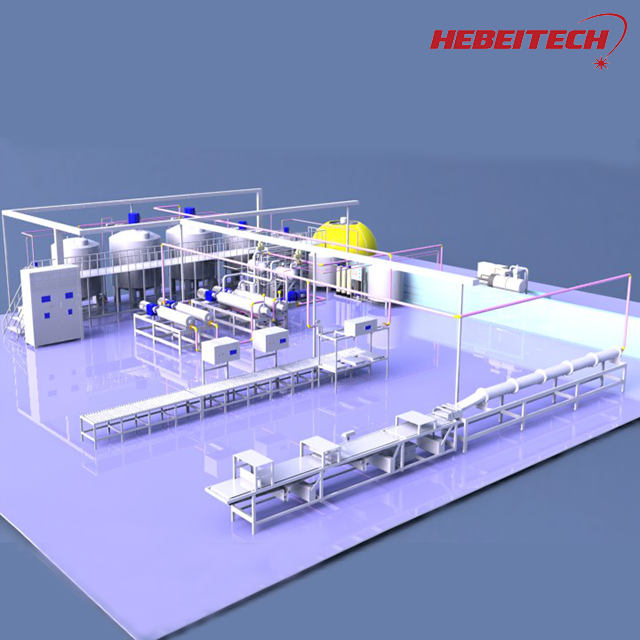

Continuous Processing

Unlike traditional batch churning, votators allow high-speed continuous production, increasing efficiency and consistency.

Advantages Over Traditional Methods:

Faster cooling → Better crystal structure control

Reduced fat separation → More uniform product

Higher throughput → Suitable for industrial-scale production

Role in Margarine Production

Margarine (an oil-in-water emulsion, often plant-based) relies heavily on votators for structuring fats and stabilizing emulsions.

Key Applications:

Emulsion Cooling & Crystallization

The oil blend (e.g., palm, soybean, or sunflower oil) is hydrogenated or interesterified to achieve the desired melting profile.

The votator rapidly cools the emulsion (~45°C → 5–20°C) under high shear, forming β' crystals (ideal for smoothness, unlike β crystals, which cause sandiness).

Plasticity & Spreadability Control

Adjusting cooling rate, shear force, and pressure modifies hardness, making it suitable for different applications (e.g., table margarine vs. bakery margarine).

Low-Fat & Dairy-Free Variants

Super votators help stabilize water-in-oil emulsions in low-fat spreads (40–60% fat) by ensuring proper crystallization and preventing phase separation.

Advantages in Margarine Production:

Prevents coarse crystals → Smoother texture

Enables flexible formulations (plant-based, trans-fat-free, etc.)

Improves shelf-life stability by optimizing fat crystal network

Technical Advantages of Super Votators

|

Feature |

Benefit |

|

High shear scraping |

Prevents fouling, ensures uniform heat transfer |

|

Precise temperature control |

Optimizes fat crystallization (β' vs. β) |

|

Pressure resistance (up to 40 bar) |

Handles viscous fats without separation |

|

Continuous operation |

Higher efficiency than batch processing |

|

Self-cleaning design |

Reduces downtime for maintenance |

Industry Examples

Butter Production:

APV, Gerstenberg Schröder, Alfa Laval and Shiputec supply votators for continuous butter-making lines.

Margarine/Spreads:

Used in plant-based margarine (e.g., made with palm or coconut oil) to mimic dairy butter’s melting behavior.

Key Considerations for Optimization

Cooling rate & shear force must be adjusted based on fat composition.

Worn scrapers reduce efficiency → Regular maintenance is critical.

Pressure settings affect emulsion stability (especially in low-fat spreads).

Conclusion

Super votators are indispensable in modern butter and margarine production, enabling:

Faster, continuous processing

Superior texture control (no graininess, ideal spreadability)

Flexibility for dairy & plant-based formulations

By optimizing cooling and crystallization, they ensure consistent quality in high-fat products while meeting industrial-scale demands.

Additional Resources

A) Original Articles :

Scraped Surface Heat Exchangers, Critical Reviews in Food Science and Nutrition,Volume 46, Issue 3

Chetan S. Rao &Richard W. Hartel

Download citation https://www.tandfonline.com/doi/abs/10.1080/10408390500315561

B) Original Articles :

Margarines, ULLMANN'S Encyclopedia of Industrial Chemistry, Wiley Online Library.

Ian P. Freeman, Sergey M. Melnikov

Download citation:https://onlinelibrary.wiley.com/doi/abs/10.1002/14356007.a16_145.pub2

C) SPV Series Similar competitive Products:

SPX Votator® II Scraped Surface Heat Exchangers

www.SPXflow.com

Visit Link: https://www.spxflow.com/products/brand?types=heat-exchangers&brand=waukesha-cherry-burrell

D) SPA series and SPV Series Similar competitive Products:

Scraped Surface Heat Exchangers

www.alfalaval.com

Visit Link:https://www.alfalaval.com/products/heat-transfer/scraped-surface-heat-exchangers/scraped-surface-heat-exchangers/

E) SPT Series Similar competitive Products:

Terlotherm® Scraped Surface Heat Exchangers

www.proxes.com

Visit Link:https://www.proxes.com/en/products/machine-families/heat-exchangers#data351

F) SPSV Series Similar competitive Products:

Perfector ® Scraped Surface Heat Exchangers

www.gerstenbergs.com/

Visit Link:https://gerstenbergs.com/polaron-scraped-surface-heat-exchanger

G) SPSV Series Similar competitive Products:

Ronothor® Scraped Surface Heat Exchangers

www.ro-no.com

Visit Link:https://ro-no.com/en/products/ronothor/

H) SPSV Series Similar competitive Products:

Chemetator® Scraped Surface Heat Exchangers

www.tmcigroup.com

Visit Link:https://www.tmcigroup.com/wp-content/uploads/2017/08/Chemetator-EN.pdf

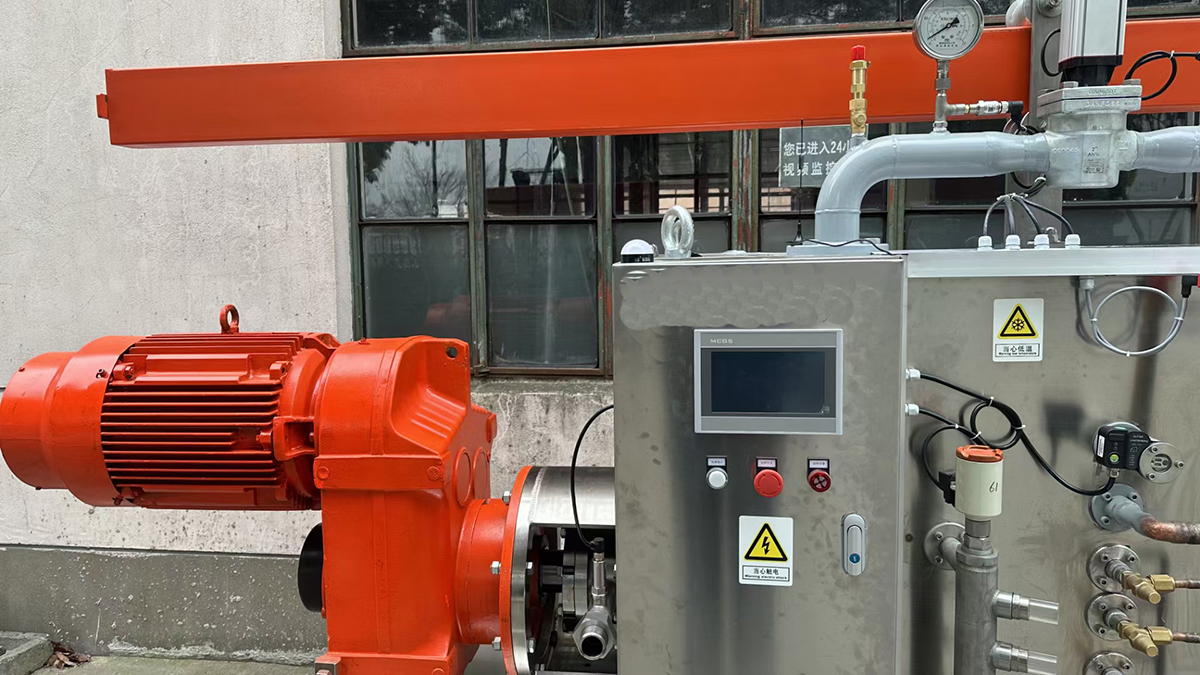

Site Commissioning