Vegetable Ghee Production Line

Vegetable Ghee Production Line

Vegetable Ghee Production Line

Production Video:https://www.youtube.com/watch?v=kiK_dZrlRbw

Vegetable ghee (also known as vanaspati ghee or hydrogenated vegetable oil) is a plant-based alternative to traditional dairy ghee. It is widely used in cooking, frying, and baking, especially in regions where dairy ghee is expensive or less accessible. The vegetable ghee production process involves hydrogenation, refining, and blending of vegetable oils to achieve a semi-solid consistency similar to traditional ghee.

Key Steps in Vegetable Ghee Production Line

A typical vegetable ghee production line includes the following stages:

1. Oil Selection & Pre-Treatment

- Raw Materials: Palm oil, soybean oil, sunflower oil, or a blend of vegetable oils.

- Filtration & Degumming: Removal of impurities and gums from crude oil.

2. Hydrogenation Process

- Hydrogenation Reactor: Vegetable oil is treated with hydrogen gas in the presence of a nickel catalyst to convert unsaturated fats into saturated fats, increasing melting point and solidity.

- Controlled Conditions: Temperature (~180–220°C) and pressure (2–5 atm) are maintained for optimal hydrogenation.

3. Deodorization & Bleaching

- Bleaching: Activated clay removes color and remaining impurities.

- Deodorization: High-temperature steam eliminates unwanted odors and flavors.

4. Blending & Crystallization

- Additives: Vitamins (A & D), antioxidants (BHA/BHT), and flavors may be added.

- Slow Cooling: The oil is cooled under controlled conditions to form a smooth, semi-solid texture.

5. Packaging

- Filling Machines: Ghee is packed in tins, jars, or pouches.

- Sealing & Labeling: Automated systems ensure airtight packaging for long shelf life.

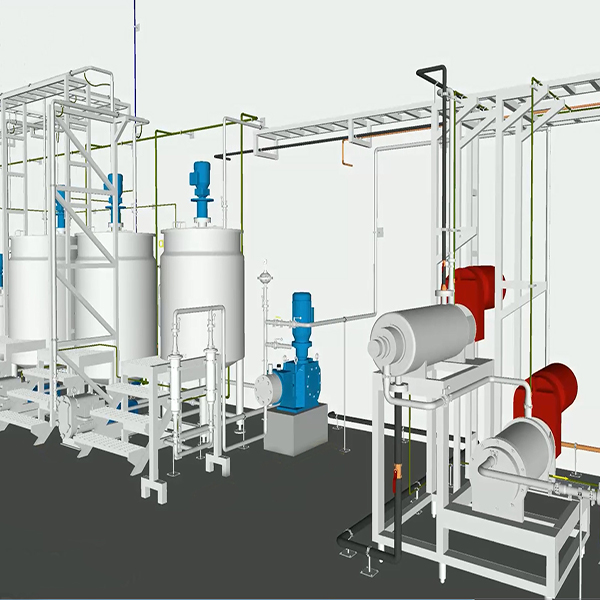

Main Equipment in a Vegetable Ghee Production Line

- Oil Storage Tanks

- Filter Press / Degumming Unit

- Hydrogenation Reactor

- Bleaching & Deodorizing Towers

- Crystallization & Tempering Tanks

- Filling & Packaging Machines

Advantages of Vegetable Ghee

✅ Longer shelf life than dairy ghee

✅ Cost-effective compared to animal-based ghee

✅ Suitable for vegans & lactose-intolerant consumers

✅ High smoke point, ideal for frying

Applications

- Cooking & frying

- Bakery & confectionery

- Ready-to-eat food industries

Conclusion

A vegetable ghee production line involves advanced refining and hydrogenation technology to produce a stable, high-quality fat product. The process ensures consistency, texture, and flavor similar to traditional ghee while being more economical and widely available.

Site Commissioning