Puff Pastry Margarine Processing Line

Puff Pastry Margarine Processing Line

Production Video:https://www.youtube.com/watch?v=3cSJknMaYd8

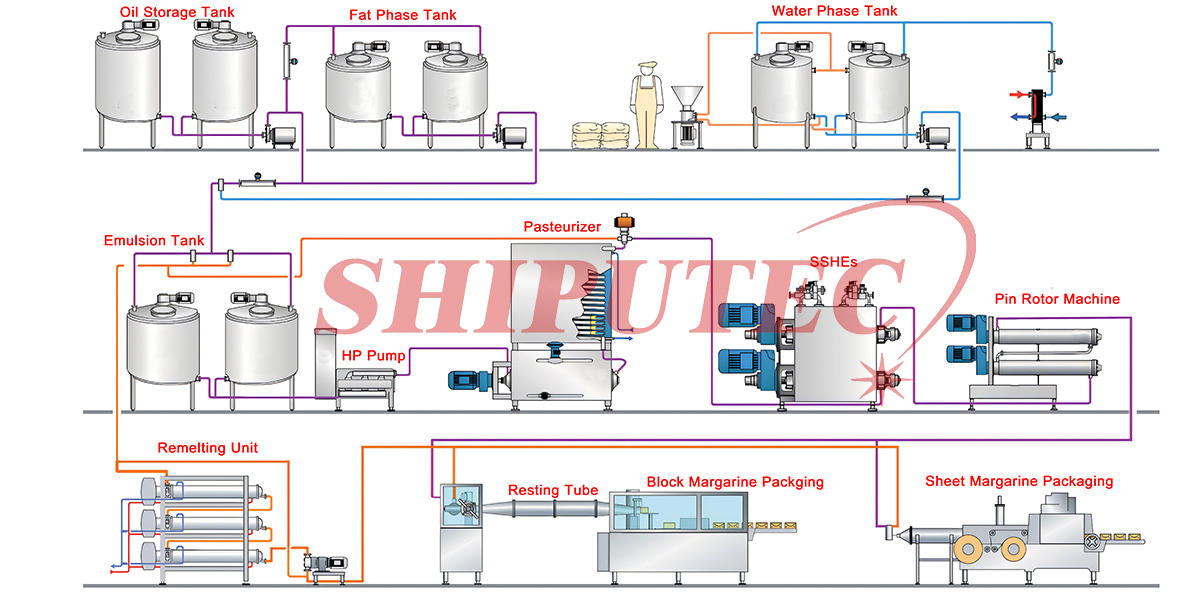

Margarine is a butter substitute made from vegetable oil, animal fat or other fat sources. Its production process and processing equipment have been highly matured after years of development. The following is a detailed process flow and introduction of key equipment:

I. Production Process of Margarin

1. Raw Material Preparation

• Main raw materials:

o Oils (about 80%): such as palm oil, soybean oil, rapeseed oil, coconut oil, etc., which need to be refined (de-gumming, de-acidification, de-coloring, de-odorization).

o Water phase (about 15-20%): skimmed milk, water, salt, emulsifiers (such as lecithin, mono-glyceride), preservatives (such as potassium sorbate), vitamins (such as vitamin A, D), flavorings, etc.

o Additives: color (β-carotene), acidity regulator (lactic acid), etc.

2. Mixing and Emulsification

• Oil phase and water phase mixing:

o The oil phase (oil + oil-soluble additives) is heated to 50-60℃ and melted.

o The water phase (water + water-soluble additives) is heated and sterilized (pasteurization, 72℃/15 seconds).

o The two phases are mixed in proportion, and emulsifiers (such as mono-glyceride, soy lecithin) are added, and a uniform emulsion (water-in-oil or oil-in-water type) is formed through high-speed stirring (2000-3000 rpm).

3. Fast cooling & crystallization (Key Step)

• Fast cooling: The emulsion is rapidly cooled to 10-20℃ through a scraped surface heat exchanger (SSHE), causing partial crystallization of the oil to form β' crystal form (key to fine texture).

• Molding: The semi-solid fat is mechanically sheared through a kneader (Pin Worker) at 2000-3000 rpm to break large crystals and form a fine and uniform fat network structure, avoiding a gritty sensation.

4. Maturing and Packaging

• Maturing: It is left to stand at 20-25℃ for 24-48 hours to stabilize the crystal structure.

• Packaging: It is filled as blocks, cups, or spray-type, and stored in refrigeration (some soft margarine can be stored at room temperature directly).

II. Core Processing Equipment

1. Pre-treatment Equipment

• Oil refining equipment: degumming centrifuge, de-acidification tower, de-coloration tank, de-odorization tower.

• Water phase processing equipment: pasteurization machine, high-pressure homogenizer (used for milk or water phase homogenization).

2. Emulsification Equipment

• Emulsion tank: stainless steel tank with stirring and heating functions (such as paddle or turbine type stirrer).

• High-pressure homogenizer: further refine the emulsion droplets (pressure 10-20 MPa).

3. Fast Cooling Equipment

• Scraped Surface Heat Exchanger (SSHE):

o Rapidly cool to sub-freezing state, with rotating scraper to prevent scaling.

o Typical brands: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (USA), Shiputec (China)

• Pin Worker:

o Shear the fat through multiple sets of pins to control crystal size.

4. Packaging Equipment

• Automatic filling machine: for blocks (25g-500g) or barrel packaging (1kg-20kg).

• Sterile packaging line: suitable for long shelf-life products (such as UHT-treated liquid margarine).

III. Process Variants

1. Soft Margarine: High proportion of liquid oil in the oil (such as sunflower oil), no need for rapid cooling molding, directly homogenized and packaged.

2. Low-fat Margarine: Fat content 40-60%, requires adding thickening agents (such as gelatin, modified starch).

3. Plant-based Margarine: All-plant oil formula, no trans fatty acids (adjust melting point through ester exchange or fractionation technology).

IV. Quality Control Key Points •

Crystal form: The β' crystal form (superior to the β crystal form) requires control of the quenching rate and mixing intensity.

• Microbial safety: The aqueous phase needs to be strictly sterilized, and the pH should be adjusted below 4.5 to inhibit bacteria.

• Oxidation stability: Add antioxidants (such as TBHQ, vitamin E) to avoid metal ion contamination.

Through the combination of the above processes and equipment, modern artificial cream can simulate the taste of butter while meeting health requirements such as low cholesterol and low saturated fat. The specific formula and process need to be adjusted according to the product positioning (such as for baking or for application on food surfaces).

Site Commissioning