Renewable Design for Ketchup Pasteurization And Cooling System – SPX Custard/Mayonnaise Processing Line China Factory – Shipu

Renewable Design for Ketchup Pasteurization And Cooling System – SPX Custard/Mayonnaise Processing Line China Factory – Shipu Detail:

SPX Custard/Mayonnaise Processing Line

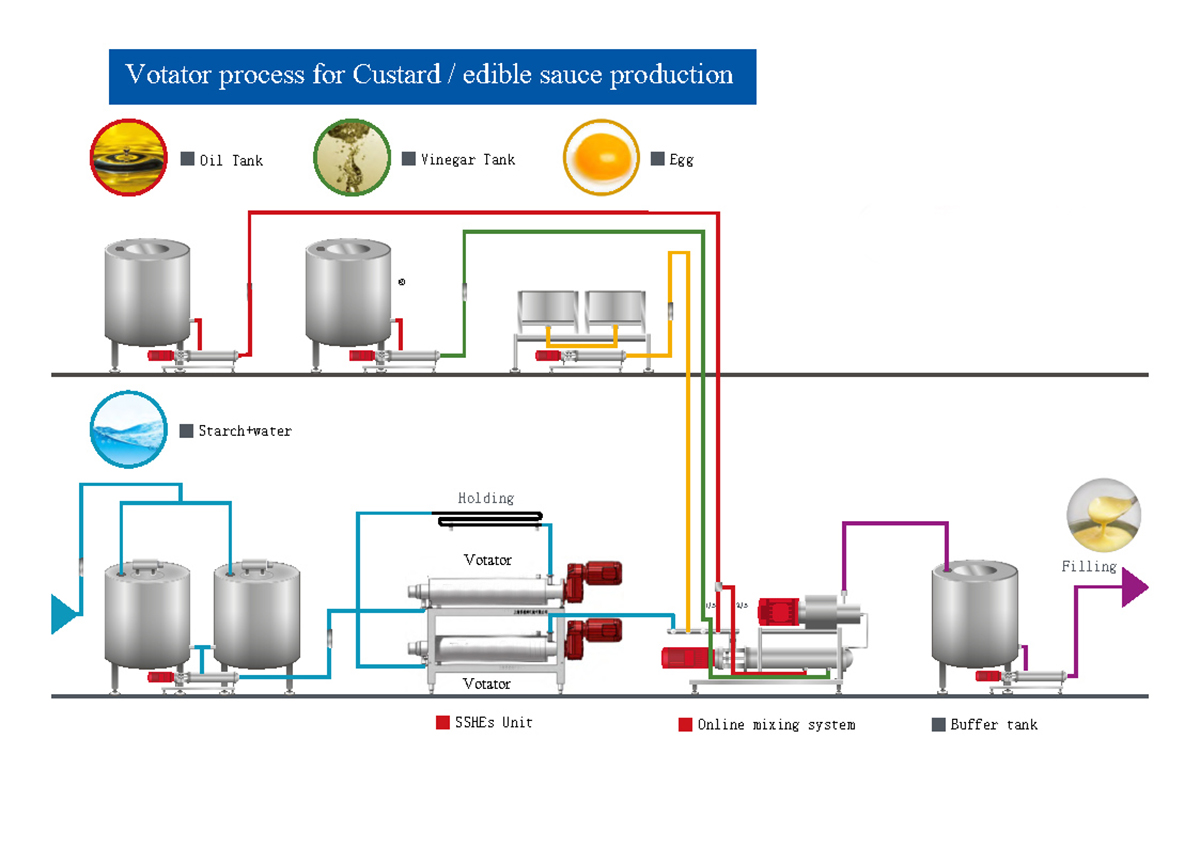

Custard / mayonnaise / edible sauce production line is a professional system for mayonnaise and the other oil / water phase emulsified ingredients. According to the production process of mayonnaise, our equipment is more suitable for mixing products whose viscosity is similar to mayonnaise.

Emulsification is the core of the production of mayonnaise and Votator series SSHEs, we adopt a production method based on the principle of on-line three-phase micro emulsification, the oil / water phase is divided in o small units, then met in the emulsifying function area, completed the complexation between emulsifier and oil / water emulsion.

This design allows the designer to specify the partition of the functional area in the whole scraped surface heat exchanger system, and better to adjust and optimize the whole manufacturing process. Such as in emulsion functional areas, Votator series strengthens emulsifying capacity, makes the oil phase to be emulsified in o microscopic liquid drops and complexing with the aqueous phase and the emulsifier the first time so that getting a stable emulsion system of oil in water, thus solving problems like too wide oil droplet size distribution, poor stability of the product type, and vulnerable to the risk of oil spills etc., which easily cause by the macro emulsification method and mixing stirring modes that interfere with each other.

In addition, SP series scraped surface heat exchangers are also used in other Heating, Cooling, Crystallization, Pasteurization, Sterilization, Gelatinize and Evaporation continuous process.

Food manufacturers from all over the world are welcome to purchase scraper heat exchangers directly from SP Machinery, and related equipment manufacturers, installation and engineering companies are also welcome to apply to become our brand agents. We provide good-quality and cheap scraped surface heat exchanger with the best price.

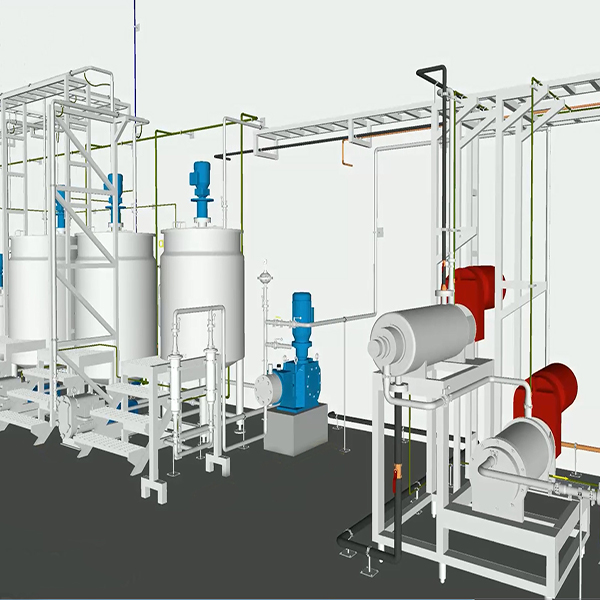

Product detail pictures:

Related Product Guide:

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Renewable Design for Ketchup Pasteurization And Cooling System – SPX Custard/Mayonnaise Processing Line China Factory – Shipu , The product will supply to all over the world, such as: Haiti, Albania, Maldives, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.